|

|

| (112 intermediate revisions by 25 users not shown) |

| Line 1: |

Line 1: |

| {| class="wikitable" style="background-color:#ffffcc;" cellpadding="10"

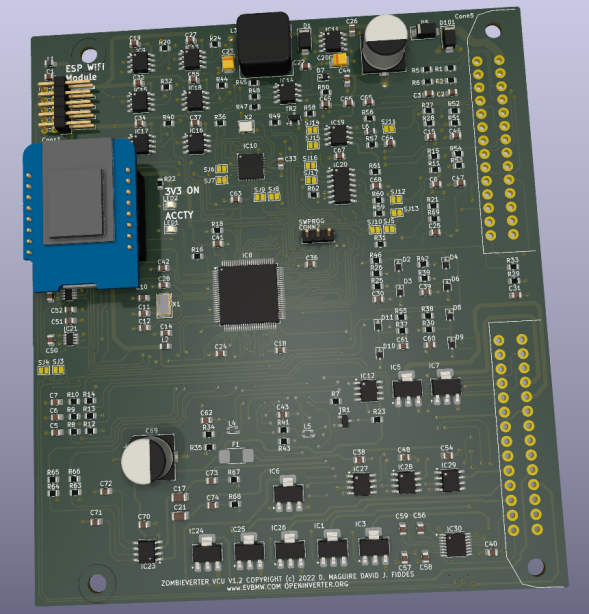

| | [[File:Zombie model.png|thumb|614x614px|ZombieVerter VCU board (NOTE: V1.2 is preproduction, V1.a is the current latest hardware revision)]] |

| |'''KINDLY NOTE:'''

| | ==Introduction == |

| *A fully tested V1a kit is now (Nov2022) available for general sale [https://www.evbmw.com/index.php/evbmw-webshop/vcu-boards/zombie-vcu here]. The boards are now shipping with the Wemos wifi module and all parts will be included in the kit. The Olimex header is still there for those who may prefer that option. See [https://openinverter.org/forum/viewtopic.php?p=48250#p48250 this post] for the Wemos wifi module mounting location.

| | '''An open-source EV conversion VCU (vehicle control unit) for controlling salvaged EV components!''' |

|

| |

|

| *''Unless you have a specific reason not to, end users should use a software release from https://github.com/damienmaguire/Stm32-vcu/releases<nowiki/>.''

| | Modern EV conversion projects often look to reuse salvaged parts from wrecked vehicles, such as the motors, batteries and chargers. |

| |}

| | |

| | The issue is that each of these components and manufacturers, use different methods of control and communication. |

|

| |

|

| '''Development continues''' and you can | | Developing controllers for these devices is complex, and time consuming and often require very dedicated communication protocols. Instead of making custom boards for every part that's been decoded, why not just make a general purpose VCU (vehicle control unit) with a verity of different types of inputs and outputs? |

| [https://openinverter.org/forum/viewtopic.php?f=3&t=1277 follow and contribute along with the development here on the forum]

| |

|

| |

|

| [https://openinverter.org/forum/viewforum.php?f=39 '''Support''' is available via this section on the forum]

| | '''''Introducing: the "ZombieVerter" VCU - a general purpose EV conversion VCU.''''' |

|

| |

|

| ==Introduction ==

| | With a large array of inputs/outputs, control logic, and a web interface for configuration and data logging. The ZombieVerter is a powerful, flexible and customizable VCU well suited for EV conversions. |

| There is a growing supply of OEM inverters, chargers, dc/dc converters, heaters, etc, requiring some control method in order to use them in a EV conversion. Instead of replacing the original logic board in these devices (with some devices it is physically impossible to do so), a vehicle control unit (vcu) which talks in its native communication protocol is a much more elegant solution. With a vcu, we can simply tell these logic boards what we want in a language they can understand, and they will do it. As far as they are concerned, they are still installed in the OEM vehicle they left the factory in.

| |

|

| |

|

| What is not elegant is having a series of bespoke vcu boards for each device. Instead, a master vcu which can handle a variety of different communication protocols(thus a variety of devices) was born; the zombiVerter !

| | It's also an open source project! |

|

| |

|

| The zombieVerter is available via evbmw's web shop https://www.evbmw.com/index.php/evbmw-webshop/vcu-boards/zombie-vcu

| | === Features === |

|

| |

|

| | ==== Hardware: ==== |

|

| |

|

| Based around the original design of the open inverter platform, the zombieVerter consists of 2 main parts:

| | * On-board WiFi |

| | * 3x high side PWM drivers |

| | * 5x low side outputs |

| | * 3x input pins (pull to ground only) |

| | * 3x CANbus interfaces |

| | * LIN bus |

| | * sync serial interface |

| | * OBD-II interface |

| | * etc. |

|

| |

|

| * a web interface

| | ==== Software: ==== |

| * a communication protocol

| |

|

| |

|

| | * Web based user interface |

| | * Contactor control |

| | * Charger control |

| | * Charge timer |

| | * Motor (inverter) control |

| | * Heater control |

| | * Water pump control |

| | * Coolant fan control |

| | * Throttle mapping |

| | * Motor regen |

| | * BMS limits |

| | * IVT shunt initialization |

| | * Data logging and graphing |

| | * etc. |

| | === Currently supported OEM hardware: === |

| | <nowiki>*</nowiki>This list is always growing and changing, and not everything is verified working |

|

| |

|

| With onboard wifi, you can access the open inverter web interface to:

| | ==== Motors/Drive units: ==== |

|

| |

|

| * set up/calibrate the different devices(inverter, charger, etc) connected to the vcu. | | * [[Nissan leaf motors|Nissan Leaf Gen1/2/3 inverter/motor via CAN]] (180V minmum voltage) |

| * tune control parameters (throttle, regen, charge speed, charge time, BMS limits, etc)

| | * [[Lexus GS450h Drivetrain|Lexus GS450h inverter / L110 gearbox via sync serial]] |

| * log info | | * Lexus GS300h inverter / L210 gearbox via sync serial |

| * graph and plot live data (rpm, amps, charge rate, etc) | | * Toyota Prius/Yaris/Auris Gen 3 inverters via sync serial |

| * update firmware | |

|

| |

|

| | * [[:Category:Mitsubishi|Mitsubishi Outlander motors/inverter]] |

| | * openinverter controller |

|

| |

|

| there are many different methods these OEM devices communicate, all which the zombieVerter can speak!

| | ==== Chargers/DCDCs: ==== |

| | * [[Nissan leaf pdm|Nissan Leaf PDM (Charger and DCDC)]] Gen1,2 & 3 |

| | * [[Mitsubishi Outlander DCDC OBC|Mitsubishi Outlander OBC (charger/DCDC)]] |

| | * [[Tesla Model S/X DC/DC Converter|tesla model S dcdc]] |

| | * [[BMW I3 Fast Charging LIM Module|CCS DC fast charge via BMW i3 LIM]] - type 2 + type 1 |

| | * [[Chademo with Zombieverter|Chademo DC fast charging]] |

| | * [[Foccci|Foccci CCS faster charger controller]] |

| | * [https://citini.com/product/evs-charge-port-controller/ EVS-Charge Port Controller] |

| | * Elcon charger |

|

| |

|

| * pwm

| | ==== Heaters: ==== |

| * canbus

| | *[[Volkswagen Heater|VAG/VW PTC water heater via LIN bus]] |

| * linbus

| | *[[VAG PTC Air Heater|VAG/VW cabin heater via LIN bus]] |

| * sync serial

| |

| * flexray | |

| * etc | |

|

| |

|

| | * [[Chevrolet Volt Water Heater|Opel Ampera / Chevy Volt 6.5kW cabin heater]] |

| | * [[Mitsubishi Outlander Water Heater|Mitsubishi outlander hybrid water heater]] |

|

| |

|

| growing list of supported OEM hardware:

| | ==== BMS: ==== |

| | * [[Nissan Leaf BMS|Nissan leaf BMS]]/battery pack |

| | * [[Renault Kangoo 36|kangoo bms]] |

| | *orion bms |

| | *[https://github.com/Tom-evnut/SimpBMS SimpBMS] |

| | *[[Isabellenhütte Heusler|ISA shunt]] |

| | *[[BMW Hybrid Battery Pack#S-Box|BMW SBOX]] |

| | *VW EBOX |

|

| |

|

| * [[Nissan leaf motors|Nissan Leaf Gen1/2/3 inverter/motor via CAN]]

| | ==== Vehicle Integration (for CANbus control of dash, etc.): ==== |

| * Nissan Leaf Gen2 PDM (Charger and DCDC)

| |

| *[[BMW I3 Fast Charging LIM Module|CCS DC fast charge via BMW i3 LIM]] - type 2 (type 1 under development?)

| |

| * Chademo dc fast charging

| |

| * [[Lexus GS450h Drivetrain|Lexus GS450h inverter / gearbox via sync serial]]

| |

| * Lexus GS300h inverter/ gearbox via sync serial

| |

| * Toyota Prius/Yaris/Auris Gen 3 inverters via sync serial

| |

| * 1998-2005 BMW 3-series (E46) CAN support | | * 1998-2005 BMW 3-series (E46) CAN support |

| * 1996-2003 BMW 5-series (E39) CAN support | | * 1996-2003 BMW 5-series (E39) CAN support |

| * 2001-2008 BMW 7-series (E65) CAN Support | | * 2001-2008 BMW 7-series (E65) CAN Support |

| | * BMW E9x CAN support |

| * Mid-2000s VAG CAN support | | * Mid-2000s VAG CAN support |

| * subaru CAN support | | * Subaru CAN support |

| *[[Chevrolet Volt Water Heater|Opel Ampera / Chevy Volt 6.5kw cabin heater]]

| |

| *vw cabin heater via lin

| |

| *[[:Category:Mitsubishi|Mitsubishi outlander motors/inverter]]

| |

| * [[VAG MEB Chargers|vw onboard chargers]] (coming soon)

| |

| | |

| | |

| It's basically an <s>rip off</s> homage and builds on other people's hard work in the shape of the following projects

| |

| *[https://github.com/jsphuebner/stm32-car STM32-CAR project]

| |

| *[https://github.com/jsphuebner/stm32-sine Openinverter]

| |

| *[https://github.com/Isaac96/SimpleISA ISA library]

| |

| *Leaf inverter driver by Celeron55

| |

| | |

| | |

| What we have as of now is the openinverter wrapper with things like :

| |

| | |

| *Throttle cal and mapping,

| |

| *Precharge and contactor control,

| |

| *Temp derating,

| |

| *BMS limits,

| |

| *for/rev/neutral control,

| |

| *Graphing and monitoring,

| |

| *Firmware updates via the web interface,

| |

| *Cruise control,

| |

| *Fuel gauge driver,

| |

| *etc

| |

| | |

| ==Hardware==

| |

| [[File:Zombv1boardb.jpg|thumb|alt=|Location of remaining parts]]

| |

| So you've ordered your kit, first things first, watch the following two videos to assemble it.

| |

|

| |

|

| Due to chip shortages (written summer 2021) the board isn't fully assembled so you will need to do some soldering, or take it to a local phone repair shop (or similar) who'll find soldering at this scale like playing with Duplo (Legos to you Yanks).

| | == Resources == |

| {| class="wikitable"

| |

| |+Parts to be fitted to ZombieVerter VCU

| |

| !Name

| |

| !Part Numer

| |

| !Alternative Part Number

| |

| |-

| |

| |CONN1

| |

| |

| |

| |

| |

| |-

| |

| |IC10

| |

| |MCP25625T

| |

| |

| |

| |-

| |

| |IC14

| |

| |TJA1020

| |

| |MCP2004

| |

| |-

| |

| |IC19

| |

| |NCV7356

| |

| |

| |

| |-

| |

| |IC20

| |

| |TJA1055T

| |

| |

| |

| |-

| |

| | IC21, IC22

| |

| |AD5160

| |

| |

| |

| |-

| |

| |IC27, IC28, IC29

| |

| |FAN3122

| |

| |

| |

| |}

| |

|

| |

|

| | * [https://openinverter.org/forum/viewtopic.php?f=3&t=1277 Development thread] |

| | * Purchasing: |

| | ** [https://www.evbmw.com/index.php/evbmw-webshop/vcu-boards/zombieverter-vcu-built Fully-built VCU boards] |

| | ** [https://www.evbmw.com/index.php/evbmw-webshop/vcu-boards/zombie-vcu Partially-built VCU boards] |

| | * [https://github.com/damienmaguire/Stm32-vcu GitHub repo] |

| | ** Hardware: [https://github.com/damienmaguire/Stm32-vcu/tree/master/Hardware/Zombie ZombieVerter V1]* |

| | ** Software: [https://github.com/damienmaguire/Stm32-vcu/releases latest stable software release] |

| | *[[pre-wired zombie wiring interface]] |

|

| |

|

| ===The enclosure kit links===

| | <nowiki>*</nowiki> '''IMPORTANT NOTE: only design files for PCB V1 are publicly available on GitHub, design files for the latest PCB release (V1.a) are only available through [https://www.patreon.com/c/evbmw/posts Damien Maguire's Patreon] and require membership at the Design Files tier or higher.''' |

|

| |

|

| You only need one, but below are two options - one with just the connector, and the other prewired with 3m long leads. The reference part numbers are 211PC562S8009 and 211PC562S0008.

| | == Assembling the VCU == |

| | Looking to build a ZombieVerter VCU yourself or the kit is missing hardware? |

|

| |

|

| *Enclosure Kit with Header, connector and pins<ref>https://www.aliexpress.com/item/32857771975.html?spm=a2g0s.9042311.0.0.39f24c4dWOmGPE (Backup: [https://web.archive.org/web/20220524004318/https://www.aliexpress.com/item/32857771975.html Web Archive])</ref> | | * [[Zombiverter hardware]] page for additional build instructions |

| *Connector and pins<ref>https://de.aliexpress.com/item/32822692950.html (Backup: [https://web.archive.org/web/20221119203700/https://www.aliexpress.us/item/2251832636378198.html?gatewayAdapt=glo2usa4itemAdapt&_randl_shipto=US Web Archive])</ref>

| |

| *Prewired connector with 3M leads (limited colors which will not match standard wire colouring conventions)<ref>https://www.aliexpress.com/item/1005003512474442.html (Backup: [http://web.archive.org/web/20221120105651/https://www.aliexpress.us/item/3256803326159690.html?gatewayAdapt=glo2usa4itemAdapt&_randl_shipto=US Web Archive])</ref>

| |

|

| |

|

| | * [https://github.com/damienmaguire/Stm32-vcu Github with PCB, schematic, pin-outs, etc] |

|

| |

|

| The kits do not come with M3 screws needed to secure the board to the enclosure (2 need to be slightly longer), and to secure the lid. Nor a gasket for the lid. | | ''The enclosure and header are required if you did not order a [https://www.evbmw.com/index.php/evbmw-webshop/vcu-boards/zombieverter-vcu-built '''fully built board''']'' |

|

| |

|

| | VCU boards from the webshop, '''''come pre-programmed''''' and '''do not require any additional steps taken to work'''. |

|

| |

|

| '''Note that in addition to the VCU, the inverter and transmission, you will require a specific CANBUS connected shunt''': [[Isabellenhütte Heusler]]

| | For programming a blank board see: [[zombieverter programing|ZombieVerter programming]] |

| | ===The enclosure kit options:=== |

|

| |

|

| | # [https://www.aliexpress.com/item/32857771975.html?spm=a2g0s.9042311.0.0.39f24c4dWOmGPE Enclosure Kit with Header, connector and pins]<ref>https://www.aliexpress.com/item/32857771975.html?spm=a2g0s.9042311.0.0.39f24c4dWOmGPE (Backup: [https://web.archive.org/web/20220524004318/https://www.aliexpress.com/item/32857771975.html Web Archive])</ref> |

| | #[https://www.aliexpress.com/item/32822692950.html Connector and pins]<ref>https://de.aliexpress.com/item/32822692950.html (Backup: [https://web.archive.org/web/20221119203700/https://www.aliexpress.us/item/2251832636378198.html?gatewayAdapt=glo2usa4itemAdapt&_randl_shipto=US Web Archive])</ref> |

| | #[https://www.aliexpress.com/item/1005003512474442.html Pre-wired connector] <ref>https://www.aliexpress.com/item/1005003512474442.html (Backup: [http://web.archive.org/web/20221120105651/https://www.aliexpress.us/item/3256803326159690.html?gatewayAdapt=glo2usa4itemAdapt&_randl_shipto=US Web Archive])</ref> |

|

| |

|

| ===Build and Configuration Videos===

| | The original connectors are from Aptiv (Delphi): |

| ====ZombieVerter VCU V1 Build Part 1====

| |

| <youtube>https://www.youtube.com/watch?v=geZuIbGHh30</youtube>

| |

|

| |

|

| {| role="presentation" class="wikitable mw-collapsible mw-collapsed"

| | * [https://www.aptiv.com/en/solutions/connection-systems/catalog/item?id=13669859_en Aptiv 56-pin connector] |

| | <strong>Highlights</strong>

| | * [https://www.aptiv.com/en/solutions/connection-systems/catalog/item?id=33511394_en Aptiv 56-pin header] |

| |-

| | * [https://www.tti.com/content/ttiinc/en/apps/part-detail.html?partsNumber=210S048&mfgShortname=FCA&productId=161404611 Removal tool for connector terminals: Manufacturer: Aptiv (formerly Delphi)] Part Number: 210S048 |

| |

| | === Videos on assembly, powering up, updating, etc: === |

| '''[https://youtu.be/geZuIbGHh30?t=33s 00:33]''' Warning and suggestion to go watch cat videos instead<br />'''[https://youtu.be/geZuIbGHh30?t=66s 01:06]''' Recap about the ZombieVerter VCU Build Part 1<br />'''[https://youtu.be/geZuIbGHh30?t=184s 03:04]''' How to get one<br />'''[https://youtu.be/geZuIbGHh30?t=215s 03:35]''' Design files currently require E10 Patreon membership/contribution if wanting to build your own<br />'''[https://youtu.be/geZuIbGHh30?t=268s 04:28]''' Components still requiring soldering<br />'''[https://youtu.be/geZuIbGHh30?t=303s 05:03]''' IC19 - 8 pin SOIC for single wire CAN (NCV7356)

| | https://www.youtube.com/watch?v=geZuIbGHh30&list=PLh-aHjjWGgLVCsAqaCL6_jmn_QqhVlRiG |

|

| |

|

| '''[https://youtu.be/geZuIbGHh30?t=360s 06:00]''' IC10 - SPI CAN controller and transceiver (MCP25625T)<br />'''[https://youtu.be/geZuIbGHh30?t=390s 06:30]''' <del>IC1,3,5,6,7,24,25,26 load driver mosfets (NCV8402)</del><br />'''[https://youtu.be/geZuIbGHh30?t=440s 07:20]''' Do you need these components?<br />'''[https://youtu.be/geZuIbGHh30?t=520s 08:40]''' Soldering begins - IC19<br />'''[https://youtu.be/geZuIbGHh30?t=550s 09:10]''' Soldering iron for SOIC parts<br />'''[https://youtu.be/geZuIbGHh30?t=567s 09:27]''' Applying flux using Damien's favorite Flux, UV80<br />'''[https://youtu.be/geZuIbGHh30?t=634s 10:34]''' Magnifier headset<br />'''[https://youtu.be/geZuIbGHh30?t=807s 13:27]''' Soldering MCP25625<br />'''[https://youtu.be/geZuIbGHh30?t=955s 15:55]''' Suggests getting an phone/computer repair shop to help out if needed<br />'''[https://youtu.be/geZuIbGHh30?t=1025s 17:05]''' Using hot air gun to warm the board and position the chip<br />'''[https://youtu.be/geZuIbGHh30?t=1174s 19:34]''' <del>Soldering NCV8402s</del><br />'''[https://youtu.be/geZuIbGHh30?t=1408s 23:28]''' Clean soldering with IPA Solvent<br />'''[https://youtu.be/geZuIbGHh30?t=1480s 24:40]''' First power up test using bench power supply to limit current to a few hundred mA<br />'''[https://youtu.be/geZuIbGHh30?t=1607s 26:47]''' 60mA current draw with no wifi board<br />'''[https://youtu.be/geZuIbGHh30?t=1655s 27:35]''' Wifi module<br />'''[https://youtu.be/geZuIbGHh30?t=1790s 29:50]''' Power up test with wifi draws 90mA<br />'''[https://youtu.be/geZuIbGHh30?t=1825s 30:25]''' Enclosure kit(s)<br />'''[https://youtu.be/geZuIbGHh30?t=2162s 36:02]''' Soldering the PCB header (56 pin)<br />'''[https://youtu.be/geZuIbGHh30?t=2668s 44:28]''' Installing in the enclosure<br />'''[https://youtu.be/geZuIbGHh30?t=3030s 50:30]''' Cameo appearance by Gome cat

| | https://www.youtube.com/watch?v=_JRa_uFyVkY&list=PLh-aHjjWGgLUWaetAmShkv6gmvk7vLaHd |

| |}

| |

|

| |

|

| {| role="presentation" class="wikitable mw-collapsible mw-collapsed"

| | == Wiring == |

| | <strong>Transcript</strong> | | [[File:ZombieVerter VCU V1 cable side pinout2.jpg|thumb|alt=|VCU pinout diagram |513x513px]]Each device requires different wiring setups, settings and power requirements. |

| |- | |

| | | |

| hello folks welcome to today's i was going to say semi-exciting episode but let's be fair this is not going to be exciting at all is it so what we're going to be dealing with today is going through the assembly of the zombiverter vcu uh pcb this is the v1 this is the release version now for those of you

| |

|

| |

|

| 00:00:31

| | <nowiki>*</nowiki>cross referencing OEM wiring diagrams is highly recommended |

|

| |

|

| That may have accidentally stumbled upon this video while searching for funny cat content i can assure you move on that hanging around here would not be a good plan furthermore if you are watching this on good old youtube i would like to inform you that it is also available free of advertisements on vimeo so now do we have those important public health announcements out of our

| | === Vehicle-specific configurations === |

| | * [[GS450H with zombieverter|GS450H with ZombieVerter]] |

| | * [[Leaf stack with zombiverter|Leaf stack with ZombiVerter]] |

| | * [[Tesla SDU with Zombieverter|Tesla SDU with ZombieVerter]] |

| | * [[Chademo with Zombieverter]] |

|

| |

|

| 00:01:02

| | === Power wiring === |

| | The ZombieVerter requires a permanent 12V supply. This is so it can manage charging, timers, and monitor systems when the car is at rest. |

|

| |

|

| Way we can proceed onwards so quick little recap because i know somebody's going to ask what is the zombie verter vcu well quite simply it is a quite simply it is a control module that is designed to sit between a vehicle that is being converted to electric drive

| | The average power draw, at idle, is 150 mA. |

|

| |

|

| 00:01:36

| | * Pin 55 to 12V- ground |

| | * Pin 56 to 12V+ positive |

|

| |

|

| And quite a few if not all of the electric drive components so this guy kind of acts as an interpreter it will take in things like our ignition switch throttle pedal various communication from the car spit out what the drivetrain may need and do the reverse as well to keep both the car and the uh drivetrain components

| | The ZombieVerter controls power/"ignition" signals to other devices (inverters, chargers, and DCDC converters), powering those devices when required. This is done by triggering an external 12V relay. '''''ZombieVerter controls the external relay using low-side switching'', meaning that it pulls the ground pin of the relay to ground.''' |

|

| |

|

| 00:02:06

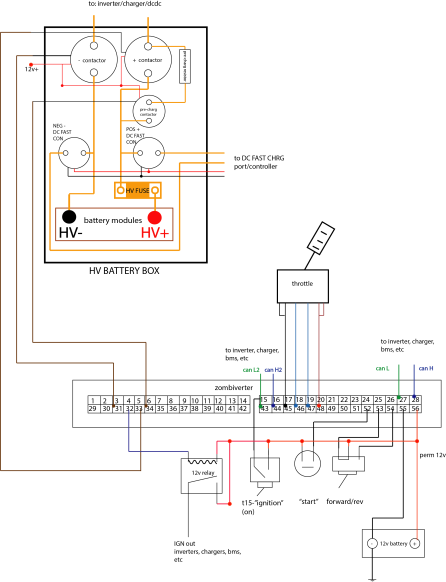

| | * [[File:Gernice-zombie.png|thumb|583x583px|general zombie and battery box wiring]]Pin 32 to ground pin on a 12V relay |

| | * Relay positive pin to 12V+ |

| | * One of the relays switch pin to 12V+ |

|

| |

|

| Happy now the aim of this particular design is to take away the programming element that is quite daunting to some people including me and make it a simple menu driven system that can be accessed over what wi-fi just using a web browser based upon the open inverter system so if you want some more information on this i do have another video

| | This effectively provides a switched 12V supply, controlled by the ZombieVerter. |

|

| |

|

| 00:02:43

| | Used to switch "enable" mode to devices via: |

|

| |

|

| Uh that gives a lot more detail on the kind of overview so i will link that in the description also but today what we're going to do is we're going to focus on the physical assembly uh that is required on the board so first thing how do we get one well currently there are two ways uh the first is that you can purchase this board

| | * Leaf inverter enable pin |

| | * Leaf PDM enable pin |

| | * Mitsubisihi OBC enable pin |

|

| |

|

| 00:03:15

| | === Contactor wiring === |

| | The Zombieveter manages the Negative, Positive and PreCharge contactors in an EV conversion. |

|

| |

|

| Along with some of these components from myself on the evbmw web shop and there will be a link in the description to that also if that doesn't quite appeal to you this is a open source uh design the design files themselves however are not as yet this is coming up to the end of july 2021 available uh freely you will have to sign up to my patreon under 10

| | This is done based off a series of voltage measurements (UDC), this voltage value (UDC) can be supplied from a variety of sources: |

|

| |

|

| 00:03:52

| | * ISA IVT shunt |

| | * Nissan leaf inverter |

| | * BMW S-BOX |

| | * etc. |

|

| |

|

| Euros a month tier to access those design files as of now once you would then have those files you can of course cancel that patreon membership and go ahead and get boards made by any of the uh pcb makers like pcbway or jlc pcb and there'll be links in the description to both of those companies also so um once you then have the board as we see here

| | ''Without a proper UDC measurement, the ZombieVerter '''will fail precharge and never go into run mode.''''' |

|

| |

|

| 00:04:27

| |

|

| |

|

| First thing that you can spot is that there are some components missing that is because due to the i guess the chip shortage stuff there's a few of the components on here that are not available from the board builders so what are those components would be the first thing that we need to work out so um

| | '''The contactor control pins on the ZombieVerter are ''low-side switching'', meaning that they pull to ground.''' |

|

| |

|

| 00:04:59

| | The positive leads from the contactors need to be connected to 12V+ and the ground leads to: |

|

| |

|

| Starting from the top here you'll see ic 19 it's a little eight pin soic uh packet this is this guy here ic 19 is an ncv 7356 single wire can transceiver one of the protocols that we support here at least in hardware so far is single wire can this can be useful

| | * Pin 31 for the negative contactor |

| | * Pin 33 for the positive contactor |

| | * Pin 34 for the pre-charge contactor |

| | === Throttle pedal wiring === |

| | The ZombieVerter supports dual-channel throttle. This redundancy is for safety in case one channel fails or drops out. It's highly recommended to use dual-channel throttle. Single-channel is an option. |

|

| |

|

| 00:05:38

| | Connect the following to the ZombieVerter pins: |

|

| |

|

| For such things as the chevy volt heater cabin heater that is which i actually have installed in my e46 touring and we will be using this very board in that vehicle the next device then that you will see is ic10 which is this qfp part which is an mcp25625 so this guy is a is a spi can controller and transceiver because we have three can with three can channels on this board

| | * Pin 45 to throttle grounds |

| | * Pin 46 to throttle channel 2 |

| | * Pin 47 to throttle channel 1 |

| | * Pin 48 to throttle positives |

|

| |

|

| 00:06:25

| | === Start, Run, and Direction wiring === |

| | The ZombieVerter requires 2 inputs to get into "drive" mode. '''These pins need to be ''pulled high'' (connected to 12V +)''' |

|

| |

|

| Finally then we have these um guys here ic5 say 7 ic577c 24 25 26 1 and 3 and those are these ncv 8402 kind of load driver mosfets so before we can do anything with the board we need to fit these components now as i say if you do purchase the board from me you will receive these parts in

| | * Pin 15 to "on" switched input (key switched to "on") |

| | * Pin 52 to "start" momentary input (momentary key switched "ignition") |

|

| |

|

| 00:07:02

| | ==== Forward and Reverse ==== |

| | These pins need to be ''pulled high'' (connected to 12V +) |

|

| |

|

| Your kit along with a wi-fi module and adapter header which we will show you later on but for now we need to go ahead and fit these components so you might say to me at this point well do i really need to fit these and the the answer is it depends what you plan to do i'll be 99 certain you would need to fit the the

| | * Pin 53 reverse |

| | * Pin 54 forward |

|

| |

|

| 00:07:37

| | ==== Brake signal ==== |

|

| |

|

| Ncv8402s because they're used for things like controlling contactors and so forth so you will definitely more than likely anyway need to fit these parts the ic10 and ic19 will depend if you intend to use the third can channel or and or if you intend to use single wire can but just for the sake of completeness here with this

| | * Pin 49 need to be ''pulled high'' (connected to 12V +) when brake is pressed |

|

| |

|

| 00:08:05

| | === Input/output pins === |

| | The ZombieVerter has a number of selectable input/output pins that can be used for a number of functions. These pins are: |

|

| |

|

| Uh video we'll go ahead and fit those components anyway so nothing to do what to do it as they say and we'll be showing you the enclosure system uh later on in the video also i'm going to make some space now here and we'll get straight into it apologies for the background noise it is feeding time for the boards after minutes so they're

| | <u>Low side Outputs.</u> |

|

| |

|

| 00:08:32

| | *GP Out 3 |

| | *GP Out 2 |

| | * Neg Contactor switch/GP Out 1 |

| | *Trans SL1- (If not using the GS450H) |

| | *Trans SL2- (If not using the GS450H) |

|

| |

|

| Busily chowing down and get another 25 kilograms of uh bird seed so let me see we want our soldering iron on so we'll start off here make sure i'm getting new folks in here now as a well as i can with ic19 or ncv735 so how i generally do these things um so far the soic part and the the drivers we're going to just use a

| | '''*Low side output connect to ground when activated.''' |

|

| |

|

| 00:09:10

| | The low side outputs in Zombie are ideal for switching relays, such as for coolant pumps. |

|

| |

|

| Small tip uh it's going to use a small little tip on my soldering iron here and we'll just individually solder them so before we do that um this is the flux that i tend to use for this kind of thing it's very cheap comes from aliexpress and it's uh kind of like a paste so it's very much like a paste because

| | <u>High side PWM.</u> |

|

| |

|

| 00:09:41

| | *PWM 3 |

| | *PWM 2 |

| | *PWM 1 |

| | *Pump PWM - Limited to GS450 Oil pump pwm or tacho pwm output |

|

| |

|

| You can't open it ah there we go okay so what i tend to do let me get that out of there is not get it on my fingers which i've just done is just use a little off cut of a cable tie that's what i find the best and just work up a little bit of the paste on the end of it and just smear it on to the pads um of the component that you want to solder just a little tin film this is going to do two things for

| | These are high side 12V outputs, usually for controlling gauges or auxiliary items than need a pwm signals. |

|

| |

|

| 00:10:12

| | '''*not suitable for controlling relays.''' |

|

| |

|

| Us the first is is it is going to adhere the component to the board when we're getting in there to actually solder it which is kind of important so i'm going to go ahead and just get out one of these little components here just using the tweezers just let it out like so now with a lot of this stuff um how you can see it and how you can you know get a good view of the thing is

| | <u>Ground Input pins</u> |

|

| |

|

| 00:10:43

| | These pins pull down to ground only. '''Do not connect any voltage to these pins.''' |

|

| |

|

| Really critical so i don't have a fancy louis rossman type microscope so what i use is just this little headset just a little cheap magnifier headset just goes on like so you can adjust this little uh plate here so you can see much better um what's going on uh with your board so i'll be doing that here we're just seeing that on my face adjusting it and we get right in

| | PB1 |

|

| |

|

| 00:11:14

| | PB2 |

|

| |

|

| Here and we'll just take our device which of course won't want to go this way so we can identify the pin one by the markings on the top and just basically sit him in there close enough to where we want him to be and he's in there now you can see i don't know how well this is going to come out on the video apologies i had bought some

| | PB3 |

|

| |

|

| 00:11:42

| | === Pin functions: === |

| | ''Note: While the web interface will allow you to select input pins or output pins, some will not actually work.'' |

|

| |

|

| Kind of lenses to go on the phone that i had hoped would allow me to kind of you know get in here a kind of a macro view but you know typically they of course didn't work or too small to fit the phone so i'm going to go ahead solder this component in as i said this is going to be a super boring video but it is one of the things that we need to do for all of our new projects is just to be able to help

| | ''example: a input switch wired but set to negContactor'' |

| | | {| class="wikitable" |

| 00:12:15

| | |+ |

| | | !Pin |

| Folks to help folks to be able to do the work themselves um and that's really the critical thing that i'm trying to promote here is it's not so much about you know me having uh evs it's about you being able to do it for yourself because we need to spread that information and knowledge around there so that you can't just

| | !IN/OUT/PWM |

| | | !Function |

| 00:12:44

| | |- |

| | | |ChaDemoAIw |

| You know have a car that you don't know how to maintain so i'm just individually soldering each of those pads at the minute it's quite easy on soic parts fairly friendly and the flux uh when it gets to heat kind of goes uh fluid which is excellent that's what we need now oh nearly dipped it into flux

| | |'''OUTPUT''' |

| | | |activates when Chademo charger handshake initiates |

| 00:13:23

| | |- |

| | | |OBCEnable |

| All right so that one's easy now the one that'll probably challenge folks the most and i include myself in this will be the um mcp25625 this is our uh our little qfp part now the trick here is a little bit of preparation as not that hard if we do that so first things first get our flux on our cable tie and just smear a nice

| | |'''OUTPUT''' |

| | | |activates as part of the ExtCharger module |

| 00:13:58

| | |- |

| | | |HeaterEnable |

| Blob around that just all over the pads like so now we're not going to put the device on there just yet what we're going to do i'm going to get our soldering iron it's a nice tin solder and we're going to just put a little bit of leaded solder on all of these pads now again the flux will

| | |'''OUTPUT''' |

| | | |activates only in run mode and when coolant pump is on* |

| 00:14:30

| | |- |

| | | |RunIndication |

| Go liquid once the heat of the soldering iron hits it and we're literally just looking to run our iron over all of those pads now the good news is that these days there's a lot of folks doing this kind of work on youtube so uh there's plenty of good tutorials out there because this is the same principle as we'd be

| | |'''OUTPUT''' |

| | | |activates when zombie is in run mode |

| 00:15:07

| | |- |

| | | |WarnIndication |

| Using for repairing laptops or phones or you know that kind of thing so now that we have our uh little bit of leaded solder on there now would be the time to excuse me introduce our device oh i need a solder fume extractor now i know that at this point i'm probably losing five out of the six people that are

| | |'''OUTPUT''' |

| | | |activates when a error occurs with the ZombieVerter |

| 00:15:38

| | |- |

| | | |CoolantPump |

| Still watching this video wow that flux is good for clearing out the throat um might be saying i can't do this i don't have this kind of gear and that's fine one of the advantages is that you know in most jurisdictions these days quite a lot of um places are now popping up uh that do uh this kind of board level repair work there does seem to be a bit

| | |'''OUTPUT''' |

| | | |activates during precharge, usually used for coolant pumps |

| 00:16:13

| | |- |

| | | |NegContactor |

| Of a renaissance on the old kind of tv repair shops from uh back in the day uh but there's but they're you know obviously doing things like repairing phones and computers which is really good um and they'll do this kind of work for you you know for very little money um i could even use this video as kind of a you know to show them what

| | |'''OUTPUT''' |

| | | |activates when the negative contactor needs to be closed. ie precharge, run, charge mode, etc |

| 00:16:42

| | |- |

| | | |BrakeLight |

| We're trying to do so i'm going to take my device i'm going to line up the dots there's a dot on the on one corner of the package and we're going to line that up with the dot here so i'm just getting it approximately in place doesn't need to be very accurate what i'm now going to do is break out the hot air and we're going to basically float that

| | |'''OUTPUT''' |

| | | |activates when a set brake light on threshold value is met |

| 00:17:08

| | |- |

| | | |ReverseLight |

| Component in there well at least i'll try to do that if i'm not uh knocking the camera out of play so just waiting for the hot air station to come up to temperature there we go i don't even need the fancy glasses at this stage now the trick we want to do is we want to warm the board up first of all so

| | |'''OUTPUT''' |

| | | |activates when reverse direction is selected |

| 00:18:00

| | |- |

| | | |CoolingFan |

| There we go you might have just seen it on camera hopefully you did but the package just jerked into the right position there should be it so i'm going to get in with my glasses there at this point yeah that looks brilliant so i'll just go around now with the going to go around those edges just flow those joints make sure everything's

| | |'''OUTPUT''' |

| | | |activates when FanTemp setpoint is reached |

| 00:18:47

| | |- |

| | | |HVActive |

| Nice and happy [Music] and do that while our board is still [Music] warm there we go so that is our um ncb7356 ic19 and mcp25625 ic10 fitted now the remainder our ncv8402 so rather than bore you completely to

| | |'''OUTPUT''' |

| | | |activates when contactors are closed and VCU is in run or charge mode |

| 00:19:41

| | |- |

| | | |BrakeVacPump |

| Tears what i will do at this point is i will fit one here on camera then i'll go ahead and fit the rest off camera and then we will go ahead power up the board to do a a test program it and then go ahead it will fit the wi-fi module and show you the enclosure system that we have and that'll be it for this particular

| | |'''DIGITAL OUTPUT''' |

| | | |activates when BrakeVacSensor threshold value is met |

| 00:20:12

| | |- |

| | | |CpSpoof |

| Episode so yes you want to fit one mcp or that ncv8402 so same principle work up some flux here and i'm just gonna just get a light coating of it i'm going to put it on all of them because obviously i'll be doing all of them here off camera that's it oh one more and it's quite a few of these guys

| | |'''PWM OUTPUT''' |

| | | |used to spoof CP signal to OBC when using a charging interface such as FOCCCI or I3LIM |

| 00:21:03

| | |- |

| | | |GS450Hpump |

| All right so i get a good smear of flux on here i'm gonna put a little bit more on these ones just to be sure there we go all right that's it it's actually finished with our flux now i can get rid of that and just cap it off so we will just take one out of this packet and i'll just make absolutely certain that it's the right part yes i will make certain it is the right part

| | |'''PWM OUTPUT''' |

| | | |used to run GS450H oil pump |

| 00:21:35

| |

| | |

| If i can see it oh my silly thing oh wow i always embarrass myself on video but i don't really need video to embarrass myself i can do it and many other ways wow they really do this badly yes eight four zero two okay so good afternoon oh yeah that turned out nice so i'm going to just set him here we'll just do it on the ic5 pad here just for

| |

| | |

| 00:22:11

| |

| | |

| Purposes of this demonstration but they'll all be the very same uh i'm in here with our soldering iron a little bit of leaded solder do there we go and finally the tab so i usually rotate the board i kind of make the board work for me um for these things and that's it there's our ncv 8402 fitted so as i say rather than boring

| |

| | |

| 00:23:19

| |

| | |

| Everyone to tears terribly i'll go ahead fit the remainder parts and then we'll come back for the power up test all righty we've got our all of the ncv8402s fitted i've just given the board a little bit of a clean off with some ipa just to get rid of flux residue you may need to get a little brush just to uh get rid of some of that but at this point we now have our board

| |

| | |

| 00:23:50

| |

| | |

| Um assembled that's that's the full um amount of component assembly that needs to be done on the board when you actually get it now there are a series of uh configuration pads here depending on what arrangement that we wish to use on country and we may need to solder some of these but that'll be

| |

| | |

| 00:24:23

| |

| | |

| That'll be covered in another episode i don't want these things to be too long and boring just enough boring that people unsubscribe now so what we want to do now is a very basic power up test we can turn our soldering iron off so let's go ahead and set up to do our basic power up test okay so for a basic power up test i'm using uh a bench power supply here

| |

| | |

| 00:24:53

| |

| | |

| Got two leads i've got a ground on this green lead i've got a positive on this brown one now i know folks are going to say oh you know what if i don't have a bench top power supply can i use a 12 volt battery answer to that question is yes and no yes you can and if you've done everything fine and there's no mistakes on the board then everything should work perfectly no because if there is a mistake on the

| |

| | |

| 00:25:25

| |

| | |

| Board and you connect a 12 volt battery to this you can get a very large current flow that can cause damage to the board or components so i would recommend some kind of a power supply uh with a current limit of a few hundred milli amps but damien i hear you say i still don't have a power supply like that okay well simple thing to do

| |

| | |

| 00:25:55

| |

| | |

| If you just have a 12 volt battery get yourself um a 12 volt tail lamp bulb so just like a brake light bulb or a just a 12 volt 21 watt bulb and put it in series with your leads so that if there is a short or something silly here it will limit the current flow so i'm going to take our positive brown wire connect this to the top right

| |

| | |

| 00:26:29

| |

| | |

| Um hope you can see that so see what i'm connecting that is just to the absolute top pin there gonna take my ground green one and connect it to the pin under that and straight away let me turn off the light here you can see we've got our little led comes on here and it says tree v tree on now we're drawing about 60 milliamps from our power supply at this point so

| |

| | |

| 00:26:58

| |

| | |

| That is a pretty good sign that everything is working as we intend it to sorry the lighting is so bad here but i hope you can see that little led there anyway so that is our basic uh power up test completed so at least we know now that the you know there's no shorts or nothing silly going on on our board and we've fitted our components properly

| |

| | |

| 00:27:31

| |

| | |

| And so forth so the next thing let me tell you down here a little bit that we're gonna want to do um is just have a quick look at the wi-fi now the wi-fi module again if you buy the board from me this comes supplied i should also point out that if you buy the board for me it comes pre-programmed as does the wi-fi module so the module um will be let's take it out of the packet

| |

| | |

| 00:28:03

| |

| | |

| Here so you can see it this little guy here and he comes with a little um holder so what i typically do when i'm fitting these is just put the i just put the little pin header in there so it'll right angle pin header my board around and sit it in like that from the top and go ahead and just kick the soldering iron back on actually i'm going to change the bait in my soldering iron to a larger one

| |

| | |

| 00:28:36

| |

| | |

| Ah just let me make this job a little bit easier all right so what i typically do here is from the top side of the board get some standard solder just pick one of the corner pins and just put a little bit of solder on them here just from this side and then like so that keeps it in place then i can flip over and just solder in the rest of the pins

| |

| | |

| 00:29:12

| |

| | |

| From the back there we go it's our wi-fi module fitted at this point uh we can do our little power up test again so just positive on the top right and ground underneath them and you'll see there that we should get a little red light on the uh wi-fi module as well or up to about 90 milliamps of current uh so that proves our wi-fi

| |

| | |

| 00:30:11

| |

| | |

| Everything else is working fine here just from a basic power point of view now so let me go ahead and make a little bit of room here for the next phase of the operation and that is the enclosure system that's been a bit of a challenge again due to the shortages and so forth to find something that was repeatable for our folks now the good news is is that we have

| |

| | |

| 00:30:42

| |

| | |

| Done so let me just actually put the board up here for a second i'll bring this into the center of the shot so the little kit that you're seeing here um comprises of a um i hope it comprises yeah there it is so this kit first of all where do i get it and how much does it cost well the end enclosure header

| |

| | |

| 00:31:14

| |

| | |

| Pins connector the whole lot comes from aliexpress express put a link in the description to that for you this whole kit i think is well under 30 euros and they have thousands of these i do not supply these you will have to purchase this for yourself now the reason for that is is that it's a big logistical thing for me

| |

| | |

| 00:31:42

| |

| | |

| To kind of bring in a lot of these stored them and shipped them and i'm just adding cost to you there's no benefit i wouldn't be doing anything with this so um what i recommend is that you just purchase this kit uh from aliexpress for yours yourself um it's gonna save you money it's gonna save me legit logistics and

| |

| | |

| 00:32:12

| |

| | |

| It just makes a lot of sense now as well as the enclosure the header and the pins on all this there's another option that you can get and i will link that in the description as well and that is if i can get it out of here oops all right is a complete wiring harness so pre-crimped ready to fit on with i think it's about three meters

| |

| | |

| 00:32:42

| |

| | |

| Of cable here all different colors all nicely terminated into the header um so this is i don't know how much this is maybe 50 or 60 euros i think um to buy this and you can buy all of these together i think from the same seller as well so makes a lot of sense and again it makes no sense for me to carry this thing um you know it can just be up to folks

| |

| | |

| 00:33:13

| |

| | |

| To decide uh what they want so and get it for themselves so all right let's break back into our kit here and have a look at it so the first thing we get uh is we get this enclosure which is quite a nice aluminium uh enclosure uh it's i don't know whether it's anodized or painted or what whatever now you will see i've bought a few of

| |

| | |

| 00:33:45

| |

| | |

| These now just for my own projects and you will see things like you know there'll be a bit of missing coating in there and you know a little bit of scratch marks and it's a bit dusty bit scratchy but you know this is going to be buried in some part of your car um so you know it doesn't you know who cares right it's it's just a readily available good quality enclosure

| |

| | |

| 00:34:16

| |

| | |

| Um so that's the actual enclosure part of it let me get rid of that bag all right so then what we get in this part is all this stuff yeah let me get rid of that bag all right so we get pins we get the connector uh the plug we got the pins for the plug we get the seal you're going to need this seal to go on the box here

| |

| | |

| 00:34:52

| |

| | |

| But for the minute this is the guy that we really want which is the header oops which mounts on our pcb so let me go ahead try not to stab myself with this very sharp scalpel and get it out of here all right [Applause] and i certainly packed this well uh a couple of different sellers i think on uh aliexpress have these i think they're very popular with

| |

| | |

| 00:35:46

| |

| | |

| Lpg and cng gas conversion ecu's i think someone on the forum said they're like some old bosch ecu connector but anywho this is our connector header and this is the component that we're going to fit next we're going to fit this to our pcb here so that basically we'll be able to get the signals out of and into the board now

| |

| | |

| 00:36:21

| |

| | |

| The pinhole sizes here are quite tight they're tight for a reason and that is because in my design of the board i need to run tracks between the pins and that means that i need to keep those pad sizes as tight as i physically can so you'll see on the back of the board there's some of that stuff too so the trick is don't go mad and try and force this

| |

| | |

| 00:36:48

| |

| | |

| We need to kind of take our time and just try and walk in all of the pins and i know that because i'm saying this now i'll make an absolute mess out of this thing so how i tend to do it is if i have the tools i need and turn off our soldering iron for a minute um where am i going here okay i just use this just a little a little small flat blade screwdriver because i'll see here straight away

| |

| | |

| 00:37:18

| |

| | |

| There was a pin that didn't want to line up so kind of just rocking the the these in here and i'll feel them starting to bite in if i look at the back of the board we'll see they're starting to line up but obviously i've got success well i've got success here or my thumb is they're starting to come true but not here at this side so if i was to just force this it would

| |

| | |

| 00:37:47

| |

| | |

| Just push the pins back it wouldn't get get it correct it just wouldn't get a correct uh fit so what i'm going to try and do is just to rock the board around a little bit like this and i might do just take it off and just use the edge of the board just to make sure the pins are all lined up properly which they are which is good to see and i'll start back over

| |

| | |

| 00:38:19

| |

| | |

| On this side actually try and make things a little bit so i'm going to try and keep this in shot for you folks as well i'm just almost there now there it is there we go and i'm just watching for anything that doesn't have a pin coming up through it which i think i'm good actually there we are

| |

| | |

| 00:38:52

| |

| | |

| I'm just pressing down now from the pins making sure that i've got no gaps here and all my pins are poking through which they are and that's my header physically slotted in there try and let you see that just so there's some kind of record of me for once doing something correctly there we go all right so i'm to just squeeze now

| |

| | |

| 00:39:28

| |

| | |

| These two guys here just to make absolutely sure and kick my soldering iron back on and what we'll do here uh is just again just make certain just even run your finger along here looking for a missing man kind of thing um like that just to be absolutely certain and then it's no prayer well get that in the in the leg um it's just pretty much come along and just solder in the uh

| |

| | |

| 00:40:08

| |

| | |

| Just solder in the solder independence speaking of missing man all right i am looking forward to the old top gun maverick and who thinks that iceman is dead i mean i can't bring myself to that thought but lots of people seem to think that and it's a concern for me so we're just gonna go ahead and do all of these here super boring on camera for you

| |

| | |

| 00:40:53

| |

| | |

| As i was saying earlier if this is something that you're not comfortable with uh and if you don't have a friend or a friend or a friend i could do this just say there are there is a bit of a renaissance on repair shops uh springing up which is really good to see uh but it does mean that there's people that have these skills now in a lot of jurisdictions where they may not have

| |

| | |

| 00:41:22

| |

| | |

| Been previously and uh definitely worth having a look around you know in your local town village area for somebody to be willing to do a little bit of this work and even if the you know the company or the shop themselves don't feel comfortable with it well maybe the technicians might be able to do it

| |

| | |

| 00:41:49

| |

| | |

| On their their own for you so there's uh quite a few options around getting past this part you just got to be guess just a little bit of leg work to uh find them now just to be absolutely clear i do not provide these assembled or provide any kind of assembly service it's just not something i have bandwidth to do

| |

| | |

| 00:42:19

| |

| | |

| Unfortunately now in regards to software i've done quite a bit of it um been a lot of really good help on the open inverter forum uh but the important thing that i'm you know trying to trying to uh generate is to get is to get as many folks involved with the project that they can you know that we can try to make this thing a a methodology to

| |

| | |

| 00:42:58

| |

| | |

| Get more people into the uh into the mindset to doing one of these conversions isn't you know particularly expensive or isn't particularly difficult and just to get away from the whole programming aspect for the end user just have it a menu driven kind of a thing so we've already got some good uh menu options we have ccs fast charging in there now i'll be

| |

| | |

| 00:43:34

| |

| | |

| Adding to demo and hopefully some traction control stuff in here as well so it's all getting quite quite interesting now that is it from our soldering point of view we can turn our soldering iron back off our pin soldered in so just a last look here just to be absolutely certain not of any pins sitting up so it helps

| |

| | |

| 00:44:08

| |

| | |

| To look down just look down here no all the pins are in perfectly there so that's good yeah that looks pretty good and that is our that's our completed board really uh so then the last pieces of the puzzle are take our enclosure a little gray gasket in here just grab that gasket

| |

| | |

| 00:44:49

| |

| | |

| And the gasket goes around the um just goes around this guy here round the header into this into this kind of a kind of a area here well i've managed to make a mess out of it on camera yay well done damien all right here we go that's our gasket fitted then our oh i'm an idiot yeah you are an idiot hold on idiot so just to

| |

| | |

| 00:45:31

| |

| | |

| Show you that i2 can screw up i managed to put the gasket on the wrong way you need these little tabs to be up the top so let's go ahead and just refit the gasket the right way obviously i did that on purpose just to demonstrate that to you folks couldn't possibly make a mistake great damien doesn't make mistakes now so one more time gasket on the right way

| |

| | |

| 00:46:03

| |

| | |

| Our pcb just sits in like this and we need four little m3 screws just to uh secure it there'll be a slightly longer screw needed here because that takes in the um the uh header whereas these just screw straight onto the pcb and that's it i'm not going to screw this board in now because i will be in the next video

| |

| | |

| 00:46:29

| |

| | |

| Um you know programming it and things like that but when it's uh in like so we take our lid and then our lid will screw in like that and then pretty much this is our completed vcu it's a nice you know solid metal case you've got tabs here where you can mount it um the one thing they don't give you in any of these kits is the gasket that would go around here

| |

| | |

| 00:47:02

| |

| | |

| So i don't know why that is um maybe other folks would be ill be able to find that particular gasket but then obviously if you know if you get this part of the kit um you know you can go ahead and crimp on pins onto your wiring uh pop them in to this guy and put the i'll put these connector things on here i'm pretty sure if i remember correctly this is a 56 pin

| |

| | |

| 00:47:36

| |

| | |

| Uh system i think there's 26 on each of these guys uh so for resources for this project if you look in the description be a link to github uh where the software is completely open source there's none of that behind any kind of paywalls or anything just the design files as i said earlier are just behind a little bit of a paywall for now um just uh

| |

| | |

| 00:48:11

| |

| | |

| Just until i make enough money to retire to lanzarote so this is it in the next episode we will uh program the device and um fix it into the and fl and closure here and i might if folks want to do a more in-depth uh video of what the various features are in here and what the various components do the there are pdf schematics and board

| |

| | |

| 00:48:44

| |

| | |

| Layouts and the actual garbers i think i have up on the github as well so there's plenty of resource there for folks to get involved with it uh there's a there's two threads over on the open inverter forum one is a dedicated support tread and the the the other one is where i do some of the development work for it so

| |

| | |

| 00:49:11

| |

| | |

| Folks that is uh i guess video one in the zombie verter vcu um assembly let's call it uh to get us you know more familiar with the board the enclosure system the header the connectors all that so i hope you have not enjoyed this um and as i say don't forget to check the links in the description both for specific links for this project and more general stuff like patreon paypal the

| |

| | |

| 00:49:49

| |

| | |

| Forum um pcb way jlcpcb and whatever else you know that might be useful i tend to leave in there so i'll leave it at that don't forget to dislike thumbs down do not share this crap with anyone unsubscribe if you have found yourself subscribed for some weird reason and um until next time then

| |

| | |

| 00:50:24

| |

| | |

| Happy vcu assembly seriously gom you decide to show up now just when the works finished like i literally just made nearly a full hour video here and you decide that now is the right time to show up all right you know right when i'm gonna get the cup of tea and chill out and that you want to show oh well ah

| |

| |}

| |

| | |

| ====ZombieVerter VCU V1 Build Part 2====

| |

| <youtube>https://youtu.be/MUhs9j9R9Mg</youtube>

| |

| | |

| {| role="presentation" class="wikitable mw-collapsible mw-collapsed"

| |

| | <strong>Highlights</strong>

| |

| |- | | |- |

| | |HeatReq |

| | |'''DIGITAL INPUT''' |

| | | | | |

| '''[https://youtu.be/MUhs9j9R9Mg?t=34s 00:34]''' Health warning and suggestion to go watch cat videos instead<br />

| |

| '''[https://youtu.be/MUhs9j9R9Mg?t=102s 01:42]''' Intro<br />

| |

| '''[https://youtu.be/MUhs9j9R9Mg?t=200s 03:20]''' Pinouts of the 56 pin connector<br />

| |

| '''[https://youtu.be/MUhs9j9R9Mg?t=256s 04:16]''' Pins 55,56 - Ground and +12V<br />

| |

| '''[https://youtu.be/MUhs9j9R9Mg?t=289s 04:49]''' Pins 53,54 - Reverse and Forward Direction. Apply +12V to the pin for the direction needed.<br />Configurable in the web interface to flip these since direction is relative<br />

| |

| '''[https://youtu.be/MUhs9j9R9Mg?t=452s 07:32]''' Pins 52 - Start. Momentarily apply +12V to send a start signal<br />

| |

| '''[https://youtu.be/MUhs9j9R9Mg?t=495s 08:15]''' Pin 51 - HV Request. Apply +12v to precharge and bring up the high voltage system<br /> (and not the drive components)<br />

| |

| '''[https://youtu.be/MUhs9j9R9Mg?t=545s 09:05]''' Pin 50 - General Purpose 12V Input. Reserved for future use<br />

| |

| '''[https://youtu.be/MUhs9j9R9Mg?t=563s 09:23]''' Pin 49 - Brake Input. Connect to brake light switch to apply +12V signaling brakes are applied<br />

| |

| '''[https://youtu.be/MUhs9j9R9Mg?t=615s 10:15]''' Pins 45,46,47,48 - Throttle. +5V power, ground, and 1 or 2 hall effect sensor inputs<br />

| |

| '''[https://youtu.be/MUhs9j9R9Mg?t=660s 11:00]''' Pins 25,26,27,28 - 3 CAN bus interfaces. CAN EXT is for vehicle/body communication,<br /> CAN EXT 2 for the ISA shunt comms,<br /> CAN EXT 3 (with solderable jumpers to change modes) is for general purpose like charger, heater control<br />

| |

| '''[https://youtu.be/MUhs9j9R9Mg?t=885s 14:45]''' Pin 24 - Local Interface Network (LIN)<br />

| |

| '''[https://youtu.be/MUhs9j9R9Mg?t=956s 15:56]''' Pins 16,17,18,19,20,21,22,23 - Toyota Hybrid Inverter specific using async serial comms.<br />

| |

| '''[https://youtu.be/MUhs9j9R9Mg?t=1041s 17:21]''' Pin 15 - Ignition T15 In. Apply +12V to turn Ignition on. Puts VCU in run mode<br />

| |

| '''[https://youtu.be/MUhs9j9R9Mg?t=1134s 18:54]''' Pins 37,38,39,40,41,42 - Toyota Hybrid Transmission shift control<br />

| |

| '''[https://youtu.be/MUhs9j9R9Mg?t=1182s 19:42]''' Pins 35,36 - POT1 & POT2. Digital potentiometer outputs to drive analog gauges (fuel, etc)<br />

| |

| '''[https://youtu.be/MUhs9j9R9Mg?t=1270s 21:10]''' Pins 32,33,34 - Low Side (LS) switches for Inverter Power, Positive side Main Contactor, Precharge Contactor<br />

| |

| '''[https://youtu.be/MUhs9j9R9Mg?t=1401s 23:21]''' Pin 31 - General Purpose +12V Output. LS switch for Negative side Main Contactor<br />

| |

| '''[https://youtu.be/MUhs9j9R9Mg?t=1441s 24:01]''' Pins 12,13,14,29,30 - Toyota Hybrid System controls<br />

| |

| '''[https://youtu.be/MUhs9j9R9Mg?t=1524s 25:24]''' Pins 10,11 - Digital to Analog Converter (DAC) 1 & 2. Reserved for future use - additional analog instruments etc.<br />

| |

| '''[https://youtu.be/MUhs9j9R9Mg?t=1593s 26:33]''' Pins 8,9 - 0-5V Analog Inputs 1 & 2. Reserved for future use (ie not implemented yet)<br />

| |

| '''[https://youtu.be/MUhs9j9R9Mg?t=1626s 27:06]''' Pins 5,6,7 - Pulse Width Modulation (PWM) 1-3 +12V output signals. Reserved for future use (ie not implemented yet)<br />

| |

| '''[https://youtu.be/MUhs9j9R9Mg?t=1676s 27:56]''' Pins 3,4 - General Purpose +12V Outputs 2 & 3. Reserved for future use (ie not implemented yet)<br />

| |

| '''[https://youtu.be/MUhs9j9R9Mg?t=1709s 28:29]''' Pins 1,2 - RS232 Rx/Tx Serial connection for alternation VCU communication (solder jumper configurable). Reserved for future expansion<br />

| |

| '''[https://youtu.be/MUhs9j9R9Mg?t=1811s 30:11]''' CAN bus connected Isabellenhutte Huesler Shunt<br />

| |

| '''[https://youtu.be/MUhs9j9R9Mg?t=2325s 38:45]''' Web Interface<br />

| |

| '''[https://youtu.be/MUhs9j9R9Mg?t=2650s 44:10]''' How to perform a software update via the web interface using a precompiled binary<br />

| |

| '''[https://youtu.be/MUhs9j9R9Mg?t=2852s 47:32]''' UI Features - Commands<br />

| |

| '''[https://youtu.be/MUhs9j9R9Mg?t=3170s 52:50]''' UI Features - Update<br />

| |

| '''[https://youtu.be/MUhs9j9R9Mg?t=3210s 53:30]''' UI Features - Parameters<br />

| |

| '''[https://youtu.be/MUhs9j9R9Mg?t=4290s 1:11:32]''' UI Features - Spot Values<br />

| |

| '''[https://youtu.be/MUhs9j9R9Mg?t=4914s 1:21:54]''' Epilogue <br />

| |

| |}

| |

|

| |

| {| role="presentation" class="wikitable mw-collapsible mw-collapsed"

| |

| | <strong>Transcript</strong>

| |

| |- | | |- |

| | | | |HVRequest |

| hello folks well this is potentially the big one um i have to talk a little bit quietly because the golden cat is currently asleep after working quite diligently on the setup here so uh i'll cut right to the core issue for those that don't really want to listen to a 40-minute

| | |'''DIGITAL INPUT''' |

| | | |NOT FUNCTIONING |

| 00:00:29

| | |- |

| | | |DCFCRequest |

| Video of me ranting the this thing the leafgen2 pdm is now functioning under zombiverter vcu control so we can run the motor we can run uh the dc dc converter and we can run the six kilowatt charger so i'm going to get into some detail on this for you uh but first obviously the obligatory uh demonstration will be required so i'm

| | |'''DIGITAL INPUT''' |

| | | |Chademo Charge Interface enable contactors to charge |

| 00:01:04

| | |- |

| | | |ProxPilot |

| Gonna go crank up the land yacht um and uh plug the chademo in to give us a jump start and then we should be able to uh should be able to get some action here it's the standby all right so uh let's see we got to turn our multimeters on so this multimeter is measuring the voltage on the 12 volt battery and this one is measuring the current

| | |'''ANALOGUE INPUT''' |

| | | |detects when charge cable is plugged in |

| 00:01:33

| |

| | |

| On the high voltage with some connections here going into the leaf harness so this is the part that would be originally connected to the vehicle obviously we've got a 12 volt battery here connected to the pdm for both uh i guess supplying the inverter pdm and the vcu which is up there on the uh up there on the bench so

| |

| | |

| 00:02:01

| |

| | |

| Uh 12.56 volts no current flow so i'm going to go ahead and uh kick on our chademo contactors in the yacht so that we can pre-charge so that is uh hv is now on so i'm going to go up to the switch podium put the ignition on and give her a flick of the start so at this point now uh we're sending can if i get my throttle pedal

| |

| | |

| 00:02:36

| |

| | |

| Give it a little squeeze yeah there's our leaf motor motoring so we are in drive mode at the minute which we normally wouldn't be when we do we'd be doing charging uh so what i'm going to do now i'm going to flick on the little switch here it's just got the 12 volt power to the pdm i'm going to flick that on i'm going to plug in a charging cable okay so we've got a click here i'm gonna

| |

| | |

| 00:03:05

| |

| | |

| Click in the evse uh the voltage on the battery is at um 14.17 and i've got five and a half amps of charging current coming from the pdm into the land yacht and the reason it's it's only five and a half amps is that the little uh evse that i've plugged in there is just a a two kilowatt granny cable um so

| |

| | |

| 00:03:38

| |

| | |

| Basically yeah if i was to push the throttle now it would spin the motor as well so we'd be charging and driving at the same time not a good situation to be in um but just for the purposes of a test here because today has been a bit of a crazy day for me it hasn't just been hacking leaf bits there's been a lot of other craziness going on that i'll hopefully

| |

| | |

| 00:04:03

| |

| | |

| Be able to talk about um at a later stage but anyway it'll certainly be marked as the day that weird stuff happened and we hacked the pdm so obviously at the minute uh we need to refine the software into vcu so that we can send power commands to the charger and send voltage commands uh to the dc to dc

| |

| | |

| 00:04:30

| |

| | |

| Now my phone is nearly dead uh because i've been on the phone all day and my voice is probably croaky as well but i've got a charger in it here so what i'm gonna do i'm going to unplug the charger and we'll try and bring you folks in here we give you a little bit of a a more detailed look around uh so that you can see what's actually going on uh turns out

| |

| | |

| 00:04:53

| |

| | |

| Driving this pdm is is not a big deal at all uh so okay stick with us alrighty so pdm this is a 6.6 kilowatt version from the nv 200 van or env or whatever they want to call it it's the complete stack so just get you down to the meters here so you can see that's our 12 volt

| |

| | |

| 00:05:22

| |

| | |

| Voltage at the minute just been measured on the battery posts this is our hv current um we're charging at five and a half amps that orange cable obviously just goes straight up into the pdm here we've got a little pre-charged circuit just with a uh electric oven element just a main contactor and a fuse

| |

| | |

| 00:05:46

| |

| | |

| Goes up to our um little distribution block and then out to the land yacht who is graciously jump starting us uh today in our endeavors so computer just working with a an arduino dewey here uh just to record can seal cedar's can flying around there on savvy can but it's all being uh generated by the uh

| |

| | |

| 00:06:18

| |

| | |

| Zombivert virtual vcu um so i'm just using i think this is a kia uh ccs socket here uh just as a type two because i don't have a type 1 i've no type 1 evses at all so i just connected up this socket here ac power comes up that white wire that's all correlated air and just goes in onto the charger inlet

| |

| | |

| 00:06:49

| |

| | |

| The control pilot and the plug present line that's your control pilot it's your plug present they're going into the harness here i had to work out from almost from first principles because those nissan warring diagrams are just terrible um so what else we got going on um the pdm doesn't need any weird signals i saw some folks over on

| |

| | |

| 00:07:20

| |

| | |

| Uh the my nissan leaf forum were really struggling with this all the pdm needs it needs 12 volts and it's got a switch on it uh it gets ground from the casing um and it needs can i and cantaloupes this is our can here uh just coming down to this twisted pair from the vcu and we're just monitoring here with the with the with the uh dewey and savvy can

| |

| | |

| 00:07:49

| |

| | |

| Set up um so really the only connections that i've made here are just 12 volts um ground can hike and low um control pilot uh proximity and there's just a relay here that just that just controls 12 volt power to the inverter um that's just an inverter

| |

| | |

| 00:08:15

| |

| | |

| Power relay from the vcu because i was at a minute i've just been lazy today and i've just programmed the vcu so the vcu thinks it's in run mode which it is because it can run the inverter and i've just tagged on the extra can messages that we need to run the pdm um so i'll just go ahead and i'll give you

| |

| | |

| 00:08:42

| |

| | |

| Another demo here and there are certain things certain things it won't do for us so far example uh let me put you guys on there let me put you guys on the multimeters here for a second so i'm gonna go ahead and unplug the evse just to prove to you that this is real so obviously you'll see there that um the dc dc

| |

| | |

| 00:09:11

| |

| | |

| Voltage stays because that's been controlled by the can and obviously it's got the hv on there um give it a little squeeze in a throttle we should still be running the motor yeah we are so uh now so if if i just plug the evse back in

| |

| | |

| 00:09:36

| |

| | |

| It will turn on the evse uh but the charger will not restart at this stage probably needs a can command to do that so i'm going to plug out the evse i'm going to just turn off see my little switch here it's going to turn off the power to the pdm so obviously with the power off the dc dc uh converter drops out

| |

| | |

| 00:10:03

| |

| | |

| I'm going to turn that back on and i'm going to throw in the evse again and you'll hear the click in the uh in the pdm and both the dc dc and the charger come right up um there's no issues there like it's not a timing sensitive kind of a thing from what i can tell it will be interesting tester ons so if i plug out evse again

| |

| | |

| 00:10:33

| |

| | |

| Turn off the pdm so let's see what happens if i with a few seconds uh turn the pdm back on and just wait okay so there's the dc dc came back up now if i plug in evse yeah pdm's gonna start up there it is so there's no there's no timing issues um

| |

| | |

| 00:11:01

| |

| | |

| Nothing of that nature that we need to worry about so that's it folks just a quick update with our 6.6 kilowatt pdm here complete leaf stack uh working um doing what it needs to do i'm going to go ahead and clean up the software in the uh in the vcu so that we've uh we can set things with it and select um

| |

| | |

| 00:11:34

| |

| | |

| Select the leaf um pdm as our charger be able to set powers and limits and stuff and uh then we can um explore further like hooking up to demo and stuff like that to it but uh yeah that's it nothing spectacular it doesn't need any high voltage interlocks relays any of that stuff at all it absolutely does not care about any of

| |

| | |

| 00:12:04

| |

| | |

| Those so um yes so uh usual folks don't forget to dislike do not share do not subscribe do not support me on patreon or paypal or any of that crap and whatever you do do not visit the links in the description where you could buy the zombivert or vcu or indeed download the code for it and

| |

| | |

| 00:12:38

| |

| | |

| Then make your own one and then i get nothing and oh no yeah no don't do that that's that's stupid um so uh right uh i'm really confused today so from everyone here at evbmw including the pdm the land yacht

| |

| | |

| 00:13:04

| |

| | |

| Gomcat myself and the kia ccs soccer um i will wish you happy leafing

| |

| | |

| |}

| |

| ====ZombieVerter VCU V1 Part 3====

| |

| | |

| <youtube>https://youtu.be/oPb4vMO17B4</youtube>

| |

| | |

| {| role="presentation" class="wikitable mw-collapsible mw-collapsed"

| |

| | <strong>Highlights</strong>

| |

| |- | | |- |

| | | | |BrakeVacSensor |

| '''[https://youtu.be/oPb4vMO17B4?t=38s 00:38]''' Intro/Recap of part 2<br /> | | |'''ANALOGUE INPUT''' |

| '''[https://youtu.be/oPb4vMO17B4?t=64s 01:04]''' Description of 2018 Nissan Leaf components used in the video<br />

| | |vacuum sensor input, use for triggering BrakeVacPump '''DIGITAL OUTPUT''' |

| '''[https://youtu.be/oPb4vMO17B4?t=227s 03:47]''' VCU, wiring harness, 12V battery, ISA shunt, contactors<br />

| |

| '''[https://youtu.be/oPb4vMO17B4?t=426s 07:06]''' 12V battery - negative to chassis ground with fuse, and ground to VCU pin 55<br />

| |

| '''[https://youtu.be/oPb4vMO17B4?t=472s 07:52]''' 12V battery - positive to PDM positive terminal and distribution block<br />

| |

| '''[https://youtu.be/oPb4vMO17B4?t=522s 08:42]''' 12V battery - permanent fused +12v from PDM positive terminal to inverter and PDM<br />

| |

| '''[https://youtu.be/oPb4vMO17B4?t=554s 09:14]''' 12V battery - permanent fused +12v to vcu, relay controlled by VCU for switched +12v to inverter and PDM<br />

| |

| '''[https://youtu.be/oPb4vMO17B4?t=641s 10:41]''' 12V battery - permanent fused +12v to contactor coil positives<br />

| |

| '''[https://youtu.be/oPb4vMO17B4?t=657s 10:57]''' 12V battery - permanent fused +12v to switch to provide things like T15 on signal to VCU<br />

| |

| '''[https://youtu.be/oPb4vMO17B4?t=762s 12:42]''' Other end of permanent 12v feed to inverter and PDM connections<br />

| |