Lexus GS450h Drivetrain

Inverter

The Lexus GS450h is a hybrid vehicle. Their inverters are suitable and attractive for DIY EVs because of:

- Good availability and price - an inverter and "transmission" can generally be purchased for less than £/€1000.

- Durability. Toyota engineers appear to have made the inverters foolproof, many inputs and outputs gracefully handle fault conditions.

- Respectable performance. Rated for a combined 250kW output.

- Ease of repurposing. Emulating the original ECU seems reasonably feasible. The transmission is a similar size and layout to many RWD transmissions.

The Lexus GS450h (2006-2012 model years) has a variety of useful components inside the inverter package:

- Two high power inverters, for the 2 motors MG1 capable of handling X(?) amps, and MG2 capable of handling Y(?) amps.

- A boost module to boost the 288v battery pack up to 650v as used in the Lexus (Note that voltages this high are not required for EV conversions).

For technical analysis of this unit, see pages 14-47 of this document: [1]

If you combine a LHD transmission with a RHD inverter (or vice versa) you might end up with a motor that is juddering, not spinning. IN this case you need to swap any two phase cables of both MG1 and MG2.

The inverter is capable of running at full speeds on pack voltages from approx. 280V upwards. The maximum allowable input voltage is 650V, so far, many have found that "standard" EV voltages of 300V-360V to be well suited.

Note that even though the inverter maximum voltage rating is 650V, a 650V battery pack is not required to run this unit. It is capable of excellent performance at lower voltages, such as the typical 300V-360V found in most EVs. However, there is the opportunity to use larger packs with this unit if required in your application.

Should a higher voltage pack be chosen in your application for any reason, the buck/boost converter can be used to power auxiliary equipment at its native voltage.

Weight: 40 lbs

Dimensions: 14" x 9-1/2" x 8-1/2"

Buck/Boost Converter

A buck/boost converter lives within the inverter housing, originally this is used to step up the 288V battery pack in the GS450h to the 650V for use in the inverter in the GS. (Note that this does not mean the inverter requires 650V to run, it is simply a maximum rating) For those using a 600+V battery pack, this converter can be used to step the voltage down to a more reasonable level to interface with chargers, DCDC converters, heaters, AC compressors, and other components which can be found in "regular" EV's (Tesla, LEAF, Volt, etc.).

This unit is rated at 30kW, making it unsuitable for traction power, but good for auxiliary devices.

Details on how to control the converter are here: https://openinverter.org/forum/viewtopic.php?f=14&t=538

For technical analysis of this unit, see pages 14-47 of this document: [1]

Transmission

For technical analysis of this transmission, see pages 46 and onward of this document:[2]

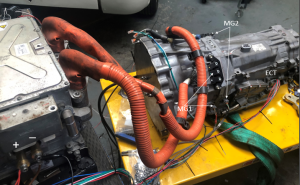

The transmission contains two "Motor-Generator" units. MG1 sits at the front of the transmission, and interfaces with the internal combustion engine through a planetary gear set. For this reason, to obtain torque from MG1, the input shaft of the transmission must be locked in place. This is usually done using a splined coupler, which is then welded onto the transmission front mount.

The input shaft on the transmission has 21 splines, with a 28mm major diameter. It is believed that there are several Toyota clutches which will have this in their centre. The original GS450h flywheel and coupler also contains the appropriate splined centre, of course.

The fluid fill port is the banjo bolt for the upper transmission cooler hose. The specified fluid is "Toyota WS" ATF.

It is a good idea to replace the two bearings in the electric oil pump before fitting a used transmission. There is a guide here[3]. Bearing part numbers are 61900-2Z and 608-2Z, you will need one of each.

The shift position lever on the right-hand side of the transmission engages the parking pawl when in the "all-the-way-back" position. All other positions disengage this pawl. The R, N, D, M positions only affect the output of the shift position sensor.

Note the following when purchasing the transmission:

- It is recommended to purchase one which has the electric oil pump fitted - these are a costly item as the bearings in them often fail, in some cases they cost more than the transmission. More on this in the Oil Pump section below.

- It is recommended to purchase a transmission which includes the wiring harness, or at least off-cuts of the connectors. Some connectors may be unavailable for purchase. There is a thread here which covers the connectors on this transmission.

Dimensions

- Overall height (oil pan to top of bellhousing) is 39cm. Bell housing is full height, i.e. 39cm diameter, when the transmission is sitting on its oil pan (as it is on my bench), the bellhousing still just about touches the bench.

- Widest point is 40cm, includes a bump for a starter motor which I don't believe the GS450h even has. Likely leftover to mate with the 2GR engine.

- Overall length including tailshaft, output flange, and pilot shaft, is 82cm.

- Transmission is tapered quite heavily, the width and height is closer to 25cm after the bellhousing, but hard to gauge due to various outcropping parts (motor cables, oil pump, PRNDL selector, etc.)

- Weight is 128kg. Unknown if this is dry or filled. Likely partially filled. Unknown if this includes oil pump and cables.

- The input shaft pokes out 29mm from the general highest point of the back of the bell housing? (e.g. set a 20cm ruler there and measure from it)

- The taper at the tip of the shaft before the splines appear fully is 6mm long. (i.e. the length of the tip portion without proper splines)

- The output flange bolt pattern is 52.5mm radius (about 91mm from hole to hole). It does not seem to have a machined flange surface, only the 22.5mm diameter ~3.2mm deep recesses around the bolt holes are machined. Pilot shaft diameter is 16mm. Internally the flange has 26 quite rectangular splines. (not 27 or so like Toyota's more common off-road applications).

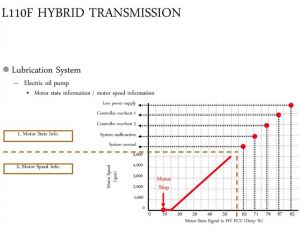

Oil Pump

Overview and location

As built, the GS450h supplies oil pressure to the gearbox using either the ICE engine or an electrically-driven external pump. With the input shaft locked in EV applications, the external pump is the only option available. As mentioned previously, this is a vital part of the setup and it's strongly recommended to buy a transmission that still has it fitted. To help with this, here is a reference photo of what to look for.

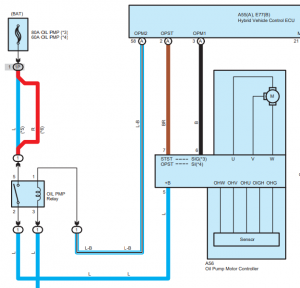

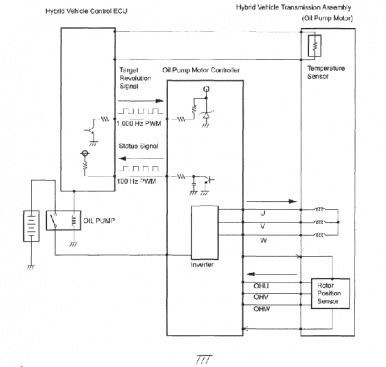

Wiring and control

The external pump also requires a controller. Although this is rarely included with the transmission, it's quite affordably and widely available (Toyota part number: G1167-30020)

Pinouts, schematics and notes

- The metal case is the ground.

- Black (pin 6) is PWM in from your controller.

- Brown (pin 7) is feedback from the oil pump. It's PWM. Do what you want with this or leave it disconnected.

- The fat blue wire (pin 5) is 12V power. The oil pump uses around 50A Max. So plan for that. Add your own relay to stop it draining your battery while the car is off.

- The PWM for this is weird, it's not just 0-100. IIRC it is 0% at both ends, and rises to 100% near the middle, then back down again. This is just based on the sound of the pump with no load, so needs more testing to find the real values.

Hardware

As per ggeter: "For those, like me, who didn't get the pump with the transmission unit, here are the part numbers for bolts and (what appears to be a metal) gasket."

Bolts (4) 90080-10197 $2.76 ea.

Gasket (1) 35142-30010 $14

The oil pump also contains 3 black rubber O-rings:

1 x 55mm internal diameter, 2.5mm cross section (for the black outer cover)

2 x 50mm internal diameter, 2.5mm cross section (between each 'layer' of the pump housing).

The oil pump motor cover is held onto the pump housing by 4 M5 x 16mm flanged screws.

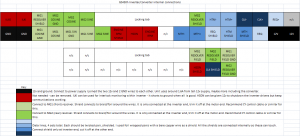

Wiring Harness Connectors

Here are a list of connectors required for the GS450h transmission & inverter if you need/wish to build the harness for your build. (It is a good idea to find components with at least the connectors to build on. As some of the connectors are impossible to obtain)

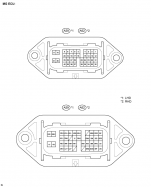

Inverter Connectors

OEM

| Connector | Part No. | Location |

|---|---|---|

| Inverter interface connector (A62) | Toyota

90980–12630 |

Black connector on the side of the inverter. This connector is not sold anywhere to our knowledge. |

Alternatives

A good alternative to this otherwise difficult to obtain connector is to replace the receptacle/header with the following parts from Molex:

Molex MX123 series

| Image | Part No. | Item | Quantity |

|---|---|---|---|

| 036638-0002 | CMC header connector 48pin | 1 | |

| 064320-1311 | CMC receptacle 48pin | 1 | |

| 064320-1301 | CMC wire cap | 1 | |

| 064323-1039 | CP terminal | 4 | |

| 064322-1039 | CP terminal | 32 | |

| 064325-1010 | CMC plug | 8 | |

| 064325-1023 | CMC plug | 4 |

Assembly Instructions

Instructions on how to assemble the MX123 connector can be found here [4].

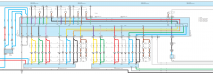

Pinout

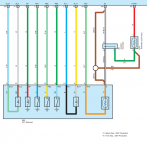

Use the following pinout to remap the internal connections from the Toyota plug to the Molex plug:

Transmission Connectors

| Connector | Part No. | Location | |

|---|---|---|---|

| ECT Solenoid (E83) | Sumitomo 6189-1092 | Located on the left hand side of the transmission above the oil pan. | |

| Shift Lever Position Sensor (E80) | Sumitomo 90980-12362 | Located on the right side of the transmission next to the shift lever inhibitor switch. | |

| MG1 & MG2 Resolver(s) (E81 & E82) | Sumitomo 6189-1240 | Two connectors located on the left side of the transmission by the bell housing. |

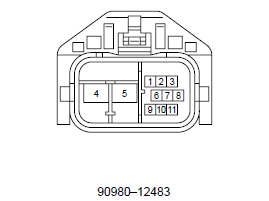

Oil Pump & Oil Pump Motor Controller

| Connector | Part No. | Location |

|---|---|---|

| Oil Pump Temperature Sensor | Sumitomo 6189-0175 | The connector is the small 2-pin connector in the middle of the harness between the oil pump and controller |

| HVECU -> Oil Pump Controller (A52) | Toyota 90980-12483 | Single large (7-way) connector on the side of the oil pump controller |

Control Schemes

ZombieVerter VCU

As of 2022, the preferred solution (and the only one under active development) is the ZombieVerter VCU

Lexus GS450h VCU (deprecated)

UPDATE: the dedicated Lexus GS450h VCU has been superseded/replaced by the ZombieVerter VCU. This section is kept active solely as legacy documentation and differs in important ways from the ZombieVerter implementation.

The Lexus GS450h VCU is an open source project to repurpose 2006-2012 Lexus GS450h inverters for DIY EV use. It consists of a circuit board and programming that communicates with the original logic board in the inverter and allows independent control of it without requiring a GS450h ECU.

An open-source VCU, designed by Damien Maguire, can be purchased as a partially populated board on his website: [5]

The VCU is an external unit that will not fit within the GS450h inverter housing. It does not replace the GS450h inverter control board, instead it interfaces with it over USART.

A full schematic for the system can be found at this link

Note that in addition to the VCU, inverter and transmission, a specific CAN bus connected shunt (ISA shunt) is required: Isabellenhütte Heusler

For those who have purchased the fully built board, the mating connectors for the VCU are Molex parts:

- 33472-2002 (Left side, grey in colour)

- 33472-2001 (Right side, black in colour)

- 33012-2002 (Crimp terminals)

- 5810130065 (Enclosure)

For partially populated board, these additional parts are required:

- 5810140011 (Header, 40 Pos.)

- 75867-101LF (CONN1, Header for Wi-Fi module)

- 5787834-1 (CONN2, USB 2.0 receptacle)

- TR10S05 (IC10, 5V DC/DC converter)

These parts are available from many electronics distributors.

VCU Firmware

Firmware to run on the VCU is available on Github : https://github.com/damienmaguire/Lexus-GS450H-Inverter-Controller

This guide relates to V3.01 available here on Github : https://github.com/damienmaguire/Lexus-GS450H-Inverter-Controller/blob/master/Software/gs450h_v3_user.ino

A video tutorial to accompany this guide and firmware is available here :https://vimeo.com/501777258

In order to aid those not familiar with programming, a new firmware with a basic serial interface is now available. This will be the default loaded onto all VCU boards sold on the EVBMW webshop as of 18/01/21.

This firmware is intended as a stop gap measure before a new Openinverter based version with a web based interface becomes available. (expect mid 2021).

Instructions for use

Connect a USB cable between the VCU and a PC.

Using a serial terminal program of your choice, connect at 115200,8,N,1.

Once connected, type ? and press enter. The following menu should then display :

=========== EVBMW GS450H VCU Version 3.01 ==============

************ List of Available Commands ************

? - Print this menu

d - Print received data from inverter

D - Print configuration data

f - Calibrate minimum throttle.

g - Calibrate maximum throttle.

i - Set max drive torque (0-3500) e.g. typing i200 followed by enter sets max drive torque to 200

q - Set max reverse torque (0-3500) e.g. typing q200 followed by enter sets max reverse torque to 200

v - Set gearbox oil pump speed (0-100%) e.g. typing v50 followed by enter sets oil pump to 50% speed

a - Select LOW gear.

s - Select HIGH gear.

z - Save configuration data to EEPROM memory

**************************************************************

The menu system allows for the display of data from both the VCU, GS450H Inverter and gearbox as well as setting of parameters such as throttle calibration and maximum torque.

To select a menu option type its associated character followed by enter.

? Will display the menu.

d Displays data from the inverter in this format :

0 1 2 3 4 5 6 7 8 9

------------------------------------------------------------------------------

00 | 0 0

10 | 0 0 0 0 0 0 0 0

20 | 0 0 0 0 0 0 0 0 0 0

30 | 0 0 0 0 0 0

40 | 0 0 0 0 0 0 0 0

50 | 0 0 0 0 0

60 |

70 |

80 | 0 0 0 0 0 0

90 | 0 0 0 0 0 0 0 0

MTH Valid: Yes Checksum: 0

DC Bus: ----v

MG1 - Speed: 0rpm Position: 0

MG2 - Speed: 0rpm Position: 0

Water Temp: 0.00c

Inductor Temp: 0.00c

Another Temp: 0c

Another Temp: 0c

D (capital or large D) displays VCU configuration data as well as information on the Gearbox status in this format :

***************************************************************************************************

Throttle Channel 1: 109

Throttle Channel 2: 53

Commanded Torque: 0

Selected Direction: DRIVE

Selected Gear: HIGH

Configured Max Drive Torque: 600

Configured Max Reverse Torque: 300

Configured gearbox oil pump speed: 40

Current valve positions:

PB1:ON

PB2:ON

PB3:ON

MG1 Stator temp: 109.69

MG2 Stator temp: 109.69

***************************************************************************************************

Throttle calibration procedure :

Set your throttle, be it a pedal or potentiometer or other, to the position of desired zero throttle.

Type f and press enter. A response like this will display:

Configured min throttle value: 109

Now press or advance the throttle to the desired position of maximum throttle.

Type g and press enter. A response like this will display:

Configured max throttle value: 633

The throttle calibration is now complete.

Next we want to set the maximum allowed drive and reverse torque values. The GS450H inverter will accept a value of between 0 and 3500 for torque.

for initial bench and vehicle testing it is advisable to limit these to low values. In this example we will set drive torque to 500 and reverse torque to 300.

First, drive torque:

Type i500 followed by enter. A response like this will display:

Configured drive torque: 500

Now reverse torque:

Type q250 followed by enter. A response like this will display:

Configured reverse torque: 250

Torque calibration is now complete.

At this point it is advised to store the now configured values to EEPROM (non volatile memory) by typing z followed by enter. A response like this will display:

Parameters stored to EEPROM

An option is provided to set the speed in % (0 to 100%) for the electric gearbox oil pump. In this example we set the speed to 50% :

Type v50 followed by enter. A response like this will display:

Configured gearbox oil pump speed: 50

I have found in testing on the E65 that 50% is a good value for keeping oil pressure up , providing cooling etc. without running the pump too hard. Your millage may vary.

An option is provided to shift between LOW and HIGH gear in the GS450H gearbox. Shifts are inhibited at MG1 or MG2 speeds above 100rpm for safety at this time.

To select LOW gear type a and press enter. A response like this will display:

LOW Gear Selected

To select HIGH gear type s and press enter. A response like this will display:

HIGH Gear Selected

It is advised to leave HIGH gear selected always at this time until further testing and development has been completed.

Finally, store all parameters to EEPROM once more by typing z and press enter. A response like this will display:

Parameters stored to EEPROM

Selecting Direction.

The firmware supports the use of the IN1 and IN2 pins of the V2 VCU as direction control inputs. Operation is as follows :

If both inputs are unconnected, NEUTRAL is selected. In neutral , no torque commands are transmitted to the inverter regardless of throttle application.

If IN1is connected to +12v , DRIVE is selected. In drive both MG1 and MG2 provide torque in a forward direction to the gearbox output shaft.

If IN2 is connected to +12v , REVERSE is selected. In reverse only MG2 provides torque in a reverse direction to the gearbox output shaft.

Currently this "simple" firmware does not support contactor control. This may be provided in a later version.

Wi-Fi Display

A Wi-Fi web browser based display is provided in order to easily visualise data from the inverter and gearbox.

Once powered, the Wi-Fi module will create an open access point with an SSID like ESP-XXXX where XXXX will be a series of letters and numbers.

Connect to this access point with any Wi-Fi enabled device (e.g. laptop, tablet, phone etc.).

Some modern devices will try to access the internet, not find it, and pop up a warning. Dismiss this and open a web browser.

Type 192.168.4.1 into the address bar and press enter. Again, some modern devices and browsers will complain that it is not a secure connection etc. Just dismiss the warning and proceed.

After a few seconds the web gauge display will appear.

Note that the voltage display is derived from the voltage reported by the inverter and both current (amps) and power (kw) gauges are inoperative as of this release.

You may wish to change the SSID and add a passphrase to the access point. To do this goto : 192.168.4.1/admin

A simple set of dialog boxes will allow the SSID, passphrase and background colour of the gauge display to be set.

In newer versions (October 2020 onwards) of the VCU Board, the default SSID and Password will be `gs450h_vcu` and `inverter123` respectively.

Development History

V1 - This board was sold tested but also as a bare logic board requiring purchase of your own components and SMD placement and soldering skills. https://www.evbmw.com/index.php/evbmw-webshop/toyota-bare-boards/gs450h-bare-pcb (No longer available).

V2 - A new board source was found to be both high quality and low cost. The boards were redesigned around the inventory of parts available from this supplier. In particular the high cost of populated and soldered boards (10x the price) from the source used to make the v1 boards is so significantly lower on the v2 that there are likely no savings by building and soldering the board yourself. Software is still in development.

Vendors

EVBMW: [5]

NOTE: There are currently no vendors who offer support on any aspects of the GS450h VCU.

Support

Community support is available on the Lexus GS450H VCU Support Thread

- ↑ 1.0 1.1 https://www.osti.gov/servlets/purl/928684

- ↑ https://www.osti.gov/servlets/purl/947393

- ↑ http://carlthomas66.blogspot.com/2016/03/lexus-gs450h-transmission-oil-pump.html (Backup: Web Archive)

- ↑ https://www.molex.com/mx_upload/family/MX123UserManual.pdf (Backup: Web Archive)

- ↑ 5.0 5.1 https://www.evbmw.com/index.php/evbmw-webshop/vcu-boards/gs450h-vcu (Backup: Web Archive)