Tesla Model 3 Drive Unit PCB Install

Introduction

This document outlines the step-by-step procedure for installing a Tesla Model 3 Drive Unit PCB in a Tesla Model 3. Please follow these instructions carefully to ensure a successful installation. The information here is derived from Damien Maguire's installation video.

Tools Required

- Soldering iron

- Solder

- Gel flux such as Kingbo RMA-218

- Vacuum desoldering gun

- 320°C

- 0.8 mm desoldering nozzle

- Blow torch or 250W soldering iron

- Tweezers

- Magnifying glass

- Torx T10 screwdriver

- Torx T20 screwdriver

- Small flat bladed screwdriver

Step 1: Fit missing components to the replacement PCB - Beta Version only

If you are using a Beta version of the replacement PCB, you will need to fit some missing components before installation. These will be supplied in a bag with the board.

Components To Fit

- U5 - ACPL-M49T-000E - Located in top right (Buffalo, New York)

- U33 - ACPL-M49T-000E - Located in the upper centre (Chicago, Illinois)

- Q983, Q43, Q982, Q42, Q981, Q41 - STD45P4LLF6 - Located across the lower part of the board

Fitting Notes

- Apply gel flux to the pads before soldering.

- Use a magnifying glass to ensure proper alignment of the two optocouplers (U5 and U33). The circle indicator on the component should match the bar on silkscreen that indicates pin 1

- When soldering the transistors solder the small pins first to hold them in place, then solder the larger tab last. You may find heavier gauge solder useful for the tab. Apply heat to the tab and allow capillary action to draw solder under the tab.

Step 2: Remove OEM PCB from the inverter housing

- Remove unnecessary hardware from the housing:

- Remove the coolant connectors from the housing to allow it to sit flat on the workbench.

- Remove the gasket around the edge of the housing carefully to avoid damaging it.

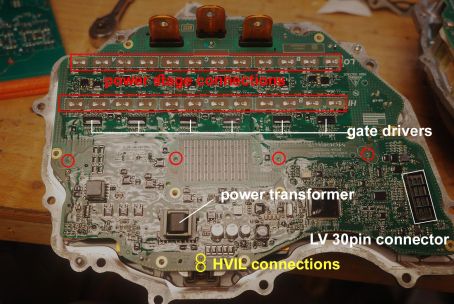

- Identify the 3 groups of components to be desoldered:

- The red rectangles indicate the power transistors

- Some drive units only have 3 of the 4 transistors fitted

- The red circles indicate the main DC bus capacitor

- The yellow circles indicate the HV interlock connections on the main DC connector

- The red rectangles indicate the power transistors

- Apply a small amount of flux to each joint to be removed

- Apply the desoldering gun and allow it to heat the joint fully. Wiggle it gentle before applying the vacuum.

- Try to hold the desoldering gun perpendicular to the PCB to ensure a good vacuum

- Additional heat from a soldering iron may help

- Use tweezers to wiggle each pin to verify it is free

- If a pin is not free try the desoldering gun again

- If problems persist, resolder the joint and try again

- Be careful not apply heat from the soldering iron or desolder gun for extended periods otherwise you might lift a pad on the PCB

- Once a pin is free move on to the next pin and repeat the process from step 3

- Carefully review all the pins are loose with tweezers

- Unscrew the 11 screws securing the PCB to the housing using the Torx T20 screwdriver.

- Unclip the 30-way lov-voltage connector clip

- Insert a flat bladed screwdriver vertically

- Squeeze towards the center of the connector whilst lifting

- Carefully lift up the PCB

- If it requires force to lift the PCB, carefully review the desoldering and mounting screws

- Flip the PCB over and use a pair of side cutters remove the black plastic clips holding the insulating shield to the underside of the PCB

- Save the insulating shield for later with the replacement PCB

Step 3: Recover gate drive components from the Tesla PCB (Optional)

Remove Gate Driver Transformer

- Apply some flux to all of the legs of the gate driver power supply transformer

- Slip a flat bladed screwdriver under the edge of the transformer and use its weight to apply a small amount of pressure

- Use a hot air gun to apply a lot of heat to the legs on one side of the transformer

- As the heat gun melts the conformal coating and solder gently lift up the leg

- Move up the side of the transformer

- Repeat on the other side

Remove Gate Driver Chips

- Apply some flux to all the pins on each gate driver chip U303, U293, U302, U292, U301 and U291

- Place a scalpel under the edge of the first chip

- Use a heat gun to desolder the chip

- As the solder melts it will be possible to lift the chip with the scalpel

- The conformal coating means the chip will not lift as easily as a regular PCB. Only a tiny amount of force will be required to break the adhesion though.

Step 4: Remove current sensor

- Unscrew the 3 screws securing the current sensor block using the Torx T10 screwdriver

- Boards fitted with pyrofuses will have 2 T10 screws.

- Release the 4 plastic clips in the centre of the sensor block

- Apply fresh solder and flux to all 4 pins on each current sensor

- Aim to bridge all 4 pins

- The process will emit some smoke as it burns off the conformal coating

- Insert the flat bladed screwdriver gently between the plastic housing and the PCB

- Apply heat with a soldering iron to one of the current sensors while levering the housing to release it

- The current sensors are bonded into the current sensor housing. Be careful not to apply a lot of force.

- Once the leads start moving move to the next sensor

- Move back and forth between the sensors until the whole assembly has been removed

- The two sensors should remain soldered to the PCB

- Desolder each current sensor by apply some flux and hot air

- Use tweezers to gently work the sensors free from the board

== Step 5: Remove 30-pin low-voltage connector

- Clamp the plastic holder on the bottom of the array of pins that make up the low-voltage connector in a vice

- Hold the PCB firmly by the far edge and apply a lifting force

- Apply a blow torch quickly to the 30 solder connections and move back and forth quickly

- As the solder melts quickly lift the PCB and torch away

- The key to success is to use a lot of heat but for a very short time

- At this point the Tesla PCB is sacrificed to obtain the connector pin array. There is no known source for connector at this point.

Alternate Technique

- As above but use a 250W soldering iron and fresh solder