Audi A2 Conversion: Difference between revisions

(→ECU) |

(→ECU) |

||

| (12 intermediate revisions by 2 users not shown) | |||

| Line 7: | Line 7: | ||

== Pin mapping == | == Pin mapping == | ||

We start out by mapping out useful pins of the original wire harness | We start out by mapping out useful pins of the original wire harness. | ||

The semi-oval connectors are used throughout the engine bay. Numbering scheme: all start with part number 1J09737xx. The last two digits define pin count, arrangement and size. Examples: | |||

* 1J0973702 - 2 pins, small | |||

* 1J0973733 - 2x3 pins, large | |||

* 1J0973703 - 3 pins, small. | |||

* 1J0973723 - 3 pins, large | |||

* 1J0973713 - 2x3 pins, small | |||

So the last digits is the number of pins per row, second to last encodes number of rows and pin size. 0=1 row, small; 1=2 rows, small; 2=1 row large, 3=2 rows, large. The matching counterparts have an 8 in place of 7, e.g. 1J09738xx. When the part number ends in a G, the casing is keyed. | |||

=== ECU === | === ECU === | ||

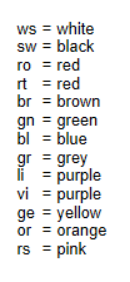

The ECU has two connector slots, a smaller one with pins 82-121 and a larger one with pins 1-81. Here we map out pins useful to us | The ECU has two connector slots, a smaller one with pins 82-121 and a larger one with pins 1-81. Here we map out pins useful to us[[File:VAG wire color codes.png|thumb]] | ||

[[File:VAG wire color codes.png|thumb]] | |||

{| class="wikitable" | {| class="wikitable" | ||

|+ECU pinout 1.4i (AUA, BBY) | |+ECU pinout 1.4i (AUA, BBY) | ||

| Line 19: | Line 26: | ||

!our function | !our function | ||

!wire color | !wire color | ||

!Engine connector | |||

|- | |- | ||

|1,2 | |1,2 | ||

| Line 24: | Line 32: | ||

|as is | |as is | ||

|br | |br | ||

| | |||

|- | |- | ||

|3 | |3 | ||

| Line 29: | Line 38: | ||

| | | | ||

|ro | |ro | ||

| | |||

|- | |- | ||

|4 | |4 | ||

| Line 34: | Line 44: | ||

|as is | |as is | ||

|ro/sw | |ro/sw | ||

| | |||

|- | |- | ||

|5 | |5 | ||

|Lambda (first) heater | |Lambda (first) heater | ||

|Reverse light | |Reverse light loopback | ||

|gr | |gr | ||

|733 1 | |||

|- | |- | ||

|28 | |28 | ||

| Line 44: | Line 56: | ||

| | | | ||

|li/bl | |li/bl | ||

| | |||

|- | |- | ||

|33 | |33 | ||

|Throttle second pot | |Throttle second pot GND | ||

|as is | |as is | ||

|gr/ge | |gr/ge | ||

| | |||

|- | |- | ||

|34 | |34 | ||

| Line 54: | Line 68: | ||

|as is | |as is | ||

|br/gn | |br/gn | ||

| | |||

|- | |- | ||

|35 | |35 | ||

| Line 59: | Line 74: | ||

|as is | |as is | ||

|ge/bl | |ge/bl | ||

| | |||

|- | |- | ||

|36 | |36 | ||

|Throttle first pot | |Throttle first pot GND | ||

|as is | |as is | ||

|br/ro | |br/ro | ||

| | |||

|- | |- | ||

|38 | |38 | ||

| Line 69: | Line 86: | ||

| | | | ||

|ws | |ws | ||

| | |||

|- | |- | ||

|39 | |39 | ||

| Line 74: | Line 92: | ||

| | | | ||

|ro/ge | |ro/ge | ||

| | |||

|- | |- | ||

|40/41 | |40/41 | ||

| Line 79: | Line 98: | ||

| | | | ||

|sw/ge sw/gr | |sw/ge sw/gr | ||

| | |||

|- | |- | ||

|43/54 | |43/54 | ||

| Line 84: | Line 104: | ||

| | | | ||

|gn/sw bl/ws | |gn/sw bl/ws | ||

| | |||

|- | |- | ||

|51/52 | |51/52 | ||

| Line 89: | Line 110: | ||

|CAN for Prius | |CAN for Prius | ||

|bl/ws ge | |bl/ws ge | ||

|733 6/3 | |||

|- | |- | ||

|55/56 | |55/56 | ||

| Line 94: | Line 116: | ||

| | | | ||

|ws/ro ro/sw | |ws/ro ro/sw | ||

| | |||

|- | |- | ||

|57 | |57 | ||

| Line 99: | Line 122: | ||

| | | | ||

|bl/ro | |bl/ro | ||

| | |||

|- | |- | ||

|58/60 | |58/60 | ||

| Line 104: | Line 128: | ||

|as is | |as is | ||

|or/br or/sw | |or/br or/sw | ||

| | |||

|- | |- | ||

|63 | |63 | ||

|Lambda (second) heater | |Lambda (second) heater | ||

| | |Drive mode selection | ||

|li/ro | |li/ro | ||

|Cable from rear lambda | |||

|- | |- | ||

|64 | |64 | ||

| Line 114: | Line 140: | ||

|vacuum pump GND | |vacuum pump GND | ||

|bl/ge | |bl/ge | ||

|722G moved to 722 | |||

|- | |- | ||

|65 | |65 | ||

| Line 119: | Line 146: | ||

| | | | ||

|ro/br | |ro/br | ||

| | |||

|- | |- | ||

|68/69 | |68/69 | ||

|Lambda (second) signal | |Lambda (second) signal | ||

| | |Drive mode LEDs | ||

|bl/br ro/li | |bl/br ro/li | ||

|Cable from rear lambda | |||

|- | |- | ||

|70/71 | |70/71 | ||

|Lambda (first) signal | |Lambda (first) signal | ||

| | |dcsw (70), prec (71) | ||

|bl sw | |bl sw | ||

|733 5/4 | |||

|- | |- | ||

|72 | |72 | ||

|Throttle second pot | |Throttle second pot 5V | ||

|as is | |as is | ||

|gr | |gr | ||

| | |||

|- | |- | ||

|73 | |73 | ||

|Throttle first pot | |Throttle first pot 5V | ||

|as is | |||

|ge/li | |||

| | | | ||

|- | |- | ||

|75/76 | |75/76 | ||

| Line 144: | Line 176: | ||

| | | | ||

|bl/sw sw/ro | |bl/sw sw/ro | ||

| | |||

|- | |- | ||

|82 | |82 | ||

| Line 149: | Line 182: | ||

| | | | ||

|gr/br | |gr/br | ||

| | |||

|- | |- | ||

|85 | |85 | ||

| Line 154: | Line 188: | ||

|brake vacuum | |brake vacuum | ||

|gr | |gr | ||

|704 | |||

|- | |- | ||

|86 | |86 | ||

| Line 159: | Line 194: | ||

| | | | ||

|ro/sw | |ro/sw | ||

| | |||

|- | |- | ||

|87 | |87 | ||

| Line 164: | Line 200: | ||

| | | | ||

|gn/sw | |gn/sw | ||

| | |||

|- | |- | ||

|88/89 | |88/89 | ||

| Line 171: | Line 208: | ||

|sw/li li/sw | |sw/li li/sw | ||

br/bl sw/gn | br/bl sw/gn | ||

| | |||

|- | |- | ||

|83/84 | |83/84 | ||

| Line 185: | Line 223: | ||

gn br/sw | gn br/sw | ||

|713 | |||

2/4, 6/1, 3/5 | |||

|- | |- | ||

|93 | |93 | ||

| Line 190: | Line 230: | ||

| | | | ||

|gr/ws | |gr/ws | ||

| | |||

|- | |- | ||

|98 | |98 | ||

| Line 195: | Line 236: | ||

|as is | |as is | ||

|gn/li | |gn/li | ||

|704 | |||

|- | |- | ||

|99 | |99 | ||

| Line 200: | Line 242: | ||

| | | | ||

|ws | |ws | ||

| | |||

|- | |- | ||

|100 | |100 | ||

| Line 205: | Line 248: | ||

|EGR pot | |EGR pot | ||

EGR mot | EGR mot | ||

| | |fake oil pressure | ||

Fake engine oil | |||

|br/li | |br/li | ||

li/ge | li/ge | ||

|1J0973713G | |||

6/5 | |||

|- | |- | ||

|102/103 | |102/103 | ||

|Ignition coil bank 1/2 | |Ignition coil bank 1/2 | ||

| | |gn/ro - LIN | ||

|gn/ws gn/ro | |gn/ws gn/ro | ||

|1J0973724 | |||

|- | |- | ||

|106 | |106 | ||

| Line 218: | Line 265: | ||

| | | | ||

|br | |br | ||

| | |||

|- | |- | ||

|108 | |108 | ||

| Line 223: | Line 271: | ||

|as is | |as is | ||

|gr/ro | |gr/ro | ||

| | |||

|- | |- | ||

|109 | |109 | ||

| Line 228: | Line 277: | ||

| | | | ||

|bl/gn | |bl/gn | ||

| | |||

|} | |||

Many positions in the connector are vacant and we populate them with signals that we need to direct to the BMS in the back of the car. I'm using a CAT5 Ethernet cable for that. It is simply routed under the seat carpet. | |||

{| class="wikitable" | |||

|+Additional pins on unused positions | |||

!# | |||

!our function | |||

!wire color | |||

!Comment | |||

|- | |||

|6 | |||

|CANH to BMS | |||

|bl | |||

| | |||

|- | |||

|7 | |||

|CANL to BMS | |||

|bl/ws | |||

| | |||

|- | |||

|8 | |||

|Permanent 12V to BMS | |||

|or | |||

| | |||

|- | |||

|9 | |||

|Switched 12V to BMS | |||

|or/ws | |||

| | |||

|- | |||

|10 | |||

|Charging active to BMS | |||

|gn/ws | |||

| | |||

|- | |||

|11 | |||

|Fuel tank simulation | |||

|gn | |||

|PB7 via NPN | |||

|- | |||

|12 | |||

|DC switch HV+ | |||

|br | |||

|Forwarded from inverter (70) | |||

|- | |||

|13 | |||

|Precharge relay | |||

|br/ws | |||

|Forwarded from inverter (71) | |||

|} | |} | ||

{| class="wikitable" | {| class="wikitable" | ||

| Line 469: | Line 567: | ||

== Silence errors == | == Silence errors == | ||

[[File:Tog2.png|thumb|Wave form to silence oil level warning]] | |||

After disconnecting the engine and removing the ECU we have 3 errors: Low coolant level, low oil, ABS/ESP. Coolant level can be silenced by simply shorting out the corresponding sense pins. We will use the coolant reservoir of the Prius inverter. We might insert a sensor for super neat integration, but not for now. | After disconnecting the engine and removing the ECU we have 3 errors: Low coolant level, low oil, ABS/ESP. Coolant level can be silenced by simply shorting out the corresponding sense pins. We will use the coolant reservoir of the Prius inverter. We might insert a sensor for super neat integration, but not for now. | ||

ABS is solved just like in [[Touran Conversion]] | |||

Same goes for oil pressure. With the sense line permanently shorted to GND we get an error at 0 rpm, with it open we get an error above 500 rpm or so. So we generate a signal that only pulls to GND above 700 rpm. I inserted the single pin into the grey 6-pin connector and bridged it to the VCU-generated signal on that same connector. | |||

Low oil can only be cured by supplying the required signal: https://wiki.a2-freun.de/wiki/index.php/G266_-_Geber_f%C3%BCr_%C3%96lstand_und_%C3%96ltemperatur | |||

I | I simulate the signal with a simple IO pin that is toggled "manually" as the time constants are rather long. | ||

[[Category:VAG]] [[Category:Conversions]] | |||

Latest revision as of 14:56, 16 March 2023

On this page we describe the conversion of an Audi A2 1.4i petrol to electric propulsion. We will use the following components:

- Nissan Leaf 24 kWh battery pack with original BMS

- Toyota Prius Gen 2 (2004-2009) transaxle with matching inverter

- openinverter Prius Gen2 motor controller

- openinverter main board running stm32-car (VCU in ECU enclosure)

Pin mapping

We start out by mapping out useful pins of the original wire harness.

The semi-oval connectors are used throughout the engine bay. Numbering scheme: all start with part number 1J09737xx. The last two digits define pin count, arrangement and size. Examples:

- 1J0973702 - 2 pins, small

- 1J0973733 - 2x3 pins, large

- 1J0973703 - 3 pins, small.

- 1J0973723 - 3 pins, large

- 1J0973713 - 2x3 pins, small

So the last digits is the number of pins per row, second to last encodes number of rows and pin size. 0=1 row, small; 1=2 rows, small; 2=1 row large, 3=2 rows, large. The matching counterparts have an 8 in place of 7, e.g. 1J09738xx. When the part number ends in a G, the casing is keyed.

ECU

The ECU has two connector slots, a smaller one with pins 82-121 and a larger one with pins 1-81. Here we map out pins useful to us

| # | orig function | our function | wire color | Engine connector |

|---|---|---|---|---|

| 1,2 | GND | as is | br | |

| 3 | permanent 12V | ro | ||

| 4 | ignition 12V | as is | ro/sw | |

| 5 | Lambda (first) heater | Reverse light loopback | gr | 733 1 |

| 28 | From generator (maybe DF) | li/bl | ||

| 33 | Throttle second pot GND | as is | gr/ge | |

| 34 | Throttle second pot (signal) | as is | br/gn | |

| 35 | Throttle first pot (signal) | as is | ge/bl | |

| 36 | Throttle first pot GND | as is | br/ro | |

| 38 | To cruise control switch * if installed | ws | ||

| 39 | Clutch pedal sensor * if installed | ro/ge | ||

| 40/41 | To Climate control display | sw/ge sw/gr | ||

| 43/54 | To instrument cluster (function unknown) | gn/sw bl/ws | ||

| 51/52 | Lambda (first) signal | CAN for Prius | bl/ws ge | 733 6/3 |

| 55/56 | Brake light switch NC/NO to +12V | ws/ro ro/sw | ||

| 57 | To cruise control switch * if installed | bl/ro | ||

| 58/60 | CAN-L CAN-H | as is | or/br or/sw | |

| 63 | Lambda (second) heater | Drive mode selection | li/ro | Cable from rear lambda |

| 64 | Charcoal filter solenoid | vacuum pump GND | bl/ge | 722G moved to 722 |

| 65 | Fuel pump relay- control | ro/br | ||

| 68/69 | Lambda (second) signal | Drive mode LEDs | bl/br ro/li | Cable from rear lambda |

| 70/71 | Lambda (first) signal | dcsw (70), prec (71) | bl sw | 733 5/4 |

| 72 | Throttle second pot 5V | as is | gr | |

| 73 | Throttle first pot 5V | as is | ge/li | |

| 75/76 | To cruise control switch * | bl/sw sw/ro | ||

| 82 | Engine speed sensor | gr/br | ||

| 85 | Intake manifold Temp/Pressure | brake vacuum | gr | 704 |

| 86 | Hall sender G40 signal | ro/sw | ||

| 87 | Engine speed sensor | gn/sw | ||

| 88/89

96/97 |

Injector 1-4 | sw/li li/sw

br/bl sw/gn |

||

| 83/84

91/92 117/118 |

Throttle body senror

Throttle body sensor Throttle body motor |

ro/gn gn/bl

ro/bl li/ro gn br/sw |

713

2/4, 6/1, 3/5 | |

| 93 | Coolant temp sensor | gr/ws | ||

| 98 | +5V wiring to engine bay | as is | gn/li | 704 |

| 99 | Knock sensor | ws | ||

| 100

114 |

EGR pot

EGR mot |

fake oil pressure

Fake engine oil |

br/li

li/ge |

1J0973713G

6/5 |

| 102/103 | Ignition coil bank 1/2 | gn/ro - LIN | gn/ws gn/ro | 1J0973724 |

| 106 | Knock sensor | br | ||

| 108 | GND for engine sensors | as is | gr/ro | |

| 109 | Intake manifold Temp/Pressure | bl/gn |

Many positions in the connector are vacant and we populate them with signals that we need to direct to the BMS in the back of the car. I'm using a CAT5 Ethernet cable for that. It is simply routed under the seat carpet.

| # | our function | wire color | Comment |

|---|---|---|---|

| 6 | CANH to BMS | bl | |

| 7 | CANL to BMS | bl/ws | |

| 8 | Permanent 12V to BMS | or | |

| 9 | Switched 12V to BMS | or/ws | |

| 10 | Charging active to BMS | gn/ws | |

| 11 | Fuel tank simulation | gn | PB7 via NPN |

| 12 | DC switch HV+ | br | Forwarded from inverter (70) |

| 13 | Precharge relay | br/ws | Forwarded from inverter (71) |

| # | Org Function | Ours | Color |

|---|---|---|---|

| 1/2 | GND | br br | |

| 3/5 | permanent 12V | gn/ge gn/ge | |

| 4/20/21

39/40 |

First Lambda | ge ro/ge bl/ge

br/ge li/gr | |

| 6 | N290 Fuel metering valve | ro/bl | |

| 7 | Fuel pump relay control | ro/br | |

| 8/10 | CAN-H CAN-L | or/sw or/br | |

| 11/16/31

32/50 |

NOX controller | sw br/ws bl

ws/sw ge/ro | |

| 12 | Heater output switch | ge/br | |

| 13/17/30 | Air mass meter | gr/ro gr/ws li/ws | |

| 14 | Thermo-switch for coolant circulation | ro/ws | |

| 15/18/43

33/19/24 |

Throttle POT1/2 (signal/Gnd/+5) | ge/li br/ro ge/li

br/gn gr/ge gr | |

| 23/46 | Climate cotroler | sw/gr sw/ge | |

| 26/45 | Radiator fan controller | sw/ge ge/gr | |

| 35 | EGT | ro/gn | |

| 36 | Brake vaccum sensor | bl/br | |

| 37 | Sensors GND | ge/bl | |

| 48/57 | Brake light switch NO/NC | ro/sw ws/ro | |

| 42 | +5V to sensors | ge/gn | |

| 49/51/52/55 | Cruise control switch * If installed | bl/sw ws sw/ro bl/ro | |

| 53 | To airbag ECU | ws/bl | |

| 59 | Instrument cluster | gn/sw | |

| 60/80 | NOX heater | br/ws br/ws | |

| 62/64 | Current supply relay | ro gr/ro | |

| 65 | Generator DF | li/br | |

| 67 | Clutch pedal switch * if fitted | ro/ge | |

| 78 | N79 crankcase breather heater | br | |

| 81/100/101

108/109 |

Coils | ro/sw ro/bl ge/gn

ge/bl gn/ge | |

| 82/90 | G28 Engine speed sensor | gr/br gr/ro | |

| 83 | G40 Hall sender | br/bl | |

| 84 | G71 Intake manifold pressure sens | ge/ro | |

| 85/87/96 | EGR sensor + motor | li/gr li/ws ro/ws | |

| 86 | Coolant temp sensor | gr/ws | |

| 88 | N316 Intake manifold flap valve | li/ge | |

| 89 | F265 Controlled cooling thermostat | ro/br | |

| 91 | G336 Intake flap potentiometer | ge/ro | |

| 94 | G247 Fuel pressure sensor | gr | |

| 99 | +5V to sensors | li/ro | |

| 105 | N205 Inlet Camsh. timing valve | li/gn | |

| 113 | N276 Fuel pressure regulating valve | gn/bl | |

| 92/93102

107/118/121 |

Throttle body | li/ge li/gr ws

ro/gn ro/bl li | |

| 103/110/111 | Knock sensor | br br ws | |

| 106 | Sensor gnd in engine bay | gr/gn | |

| 114/115

116/117 119/120 |

Injectors 1-4 | br/ge br/ws

br/gn br/ro br/bl br/sw |

Silence errors

After disconnecting the engine and removing the ECU we have 3 errors: Low coolant level, low oil, ABS/ESP. Coolant level can be silenced by simply shorting out the corresponding sense pins. We will use the coolant reservoir of the Prius inverter. We might insert a sensor for super neat integration, but not for now.

ABS is solved just like in Touran Conversion

Same goes for oil pressure. With the sense line permanently shorted to GND we get an error at 0 rpm, with it open we get an error above 500 rpm or so. So we generate a signal that only pulls to GND above 700 rpm. I inserted the single pin into the grey 6-pin connector and bridged it to the VCU-generated signal on that same connector.

Low oil can only be cured by supplying the required signal: https://wiki.a2-freun.de/wiki/index.php/G266_-_Geber_f%C3%BCr_%C3%96lstand_und_%C3%96ltemperatur

I simulate the signal with a simple IO pin that is toggled "manually" as the time constants are rather long.