There are several layers of defence we can apply to the overall coolant leak issue. Replacing the seal et al will (usually, supposedly, temporarily?) stop coolant ingress. Great, problem solved . . . for now.

Based on historic trends, we're making a reasonable assumption that the rotor seal will leak again. We can put in place protective measures to slow the damage caused by a repeat incident.

I think that the mods that Johan performed on his repair are fine, and I like that he walked us through his assumptions and reasoning. Most of the screengrabs below are from

one of his excellent YT vids on this topic.

Possible defensive measures that could be incorporated into a seal repair process include:

1) Seal off the rotor side from the inverter side.

Alex @ QCP says that he installs a silicone gasket there to replace a paper gasket (not clear to me what that means) and then uses Form-A-Gasket (a Permatex-branded RTV [Room Temperature Vulcanize] silicone-based sealant), to fill that cavity. I think RTV would work as well as Johan's two-part potting compound, though it might not look quite as nice

The separate 4-wire bundle needs its own, separate application of sealant as well, I think.

One problem that arose during Johan's assembly was that a jig is probably needed to hold the bus bars in the proper position, prior to potting using his pour method -- and probably is a good idea using a caulking-style silicone injection method. He found slight misalignment of the bus bars with the inverter connector locations during assembly, a very easy thing to overlook. The bars/connector pads misalignment shown below is not parallax error, and Johan had to persuade the bars to move to the correct locations, possibly compromising the potting material's seal.

So, a jig.

2) Create a weep hole under the seal, to dump overboard seal leakage right at the first leak point.

Funny, back in the day,

every automotive water pump had a weep hole between the coolant seal and the pump shaft bearing.

On the Tesla LDU, installing a weep hole is a well-trod path that others have done successfully. Drain line or not -- and if so, the type of fitting -- are a preference/optional item, but just providing a safer place for leakage to exit is a very good start:

3) Create a weep hole/inspection hole/sensor hole in the bottom of the stator housing.

This is a hole at a low point in the rotor cavity, where a one-wire sensor can be installed in a eg 5mm hole, to provide an in-car warning annunciator (light, buzzer, SMS msg, etc.); or, it can be used as an additional drain point.

AFAIK, this was the first documented drain location/method for an LDU.

https://www.myrav4ev.com/forum/viewtopi ... 419#p29419

https://www.youtube.com/watch?v=ps2gha4w5YE[url]

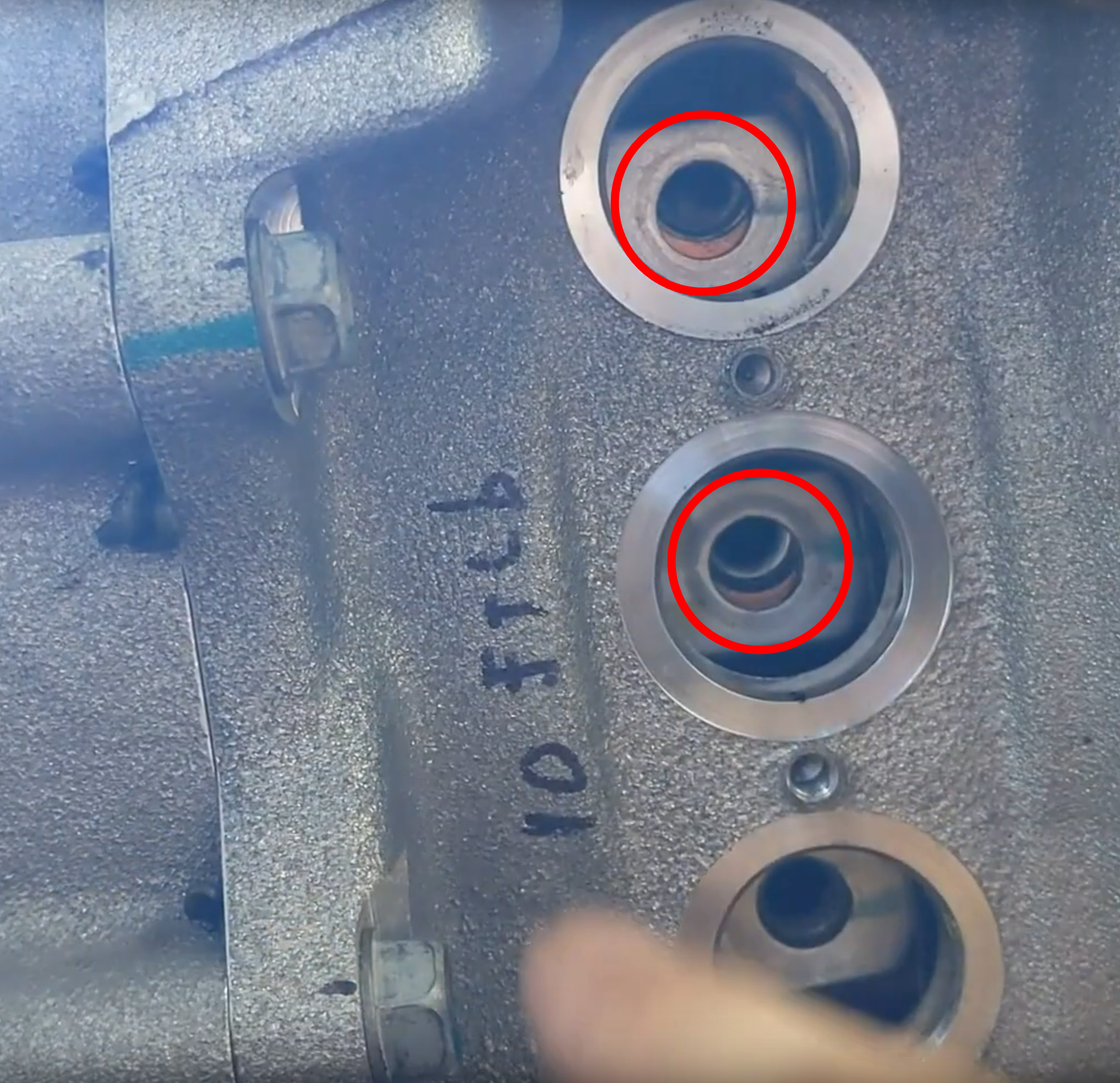

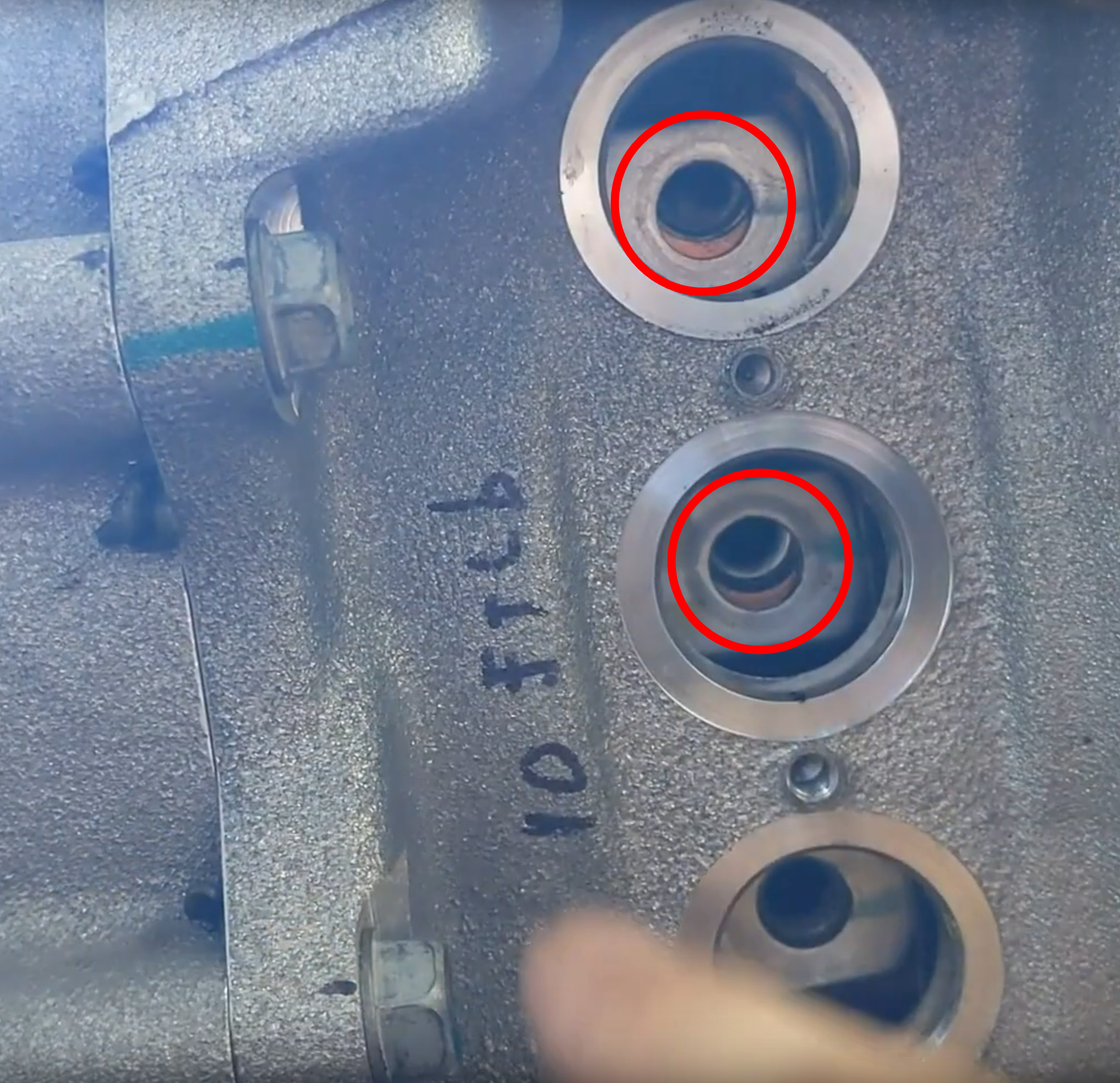

4) Seal the existing vent balance hole on the rotor end support (between reluctor chamber and rotor cavity), and install a second external vent, Toyota 33197-0R010 (USD$8 ea.). Aerosolized coolant that being whipped about by the reluctor is thus slowed from moving through the OEM vent hole to the rotor cavity, giving it time to find its way to the weep hole that was installed:

5) Add a third external vent to rotor end support, between rotor cavity and outside:

6) Add an inverter-side drain.

I'm of two minds on inverter drains.

QCP is selling their "drain kit" that taps the inverter side. But, I've read no evidence that

coolant leaks have ever started on the inverter side, but there seems to be at least

one instance where the gearbox lubricant escaped to the inverter. So, while I'm not particularly worried about monitoring the inverter side for coolant, coolant in the inverter isn't the only thing that needs external validation

7) Less damaging coolant.

An idea that has been brought up is to discontinue cooling with a water-based coolant (ie use oil, or a glycol-based

waterless coolant). Internal leaks would then cause less immediate, and less expensive, damage, giving more time for a leak to be detected. Using waterless coolant will make electronic detection of a leak challenging, as the current leak detection schemes are either conductivity- or vertical-level based. Is there an electronic glycol detector?