From what I’ve learned, all LDU models can suffer with ‘premature’ motor rotor bearing and pinion bearing failure on mid to higher mileage cars. However, more serious, is a failure of the coolant tube seal which is located on the encoder end of the motor – this fault is common in drive units prior to the ‘Q’ part number revision – however Q model numbers are also affected as seen in this case.

If you’re lucky, bearing failure will just be noisy and can be referred to as ‘milling’ – get it early and it’s no big deal. A coolant tube seal failure is another story altogether and can be catastrophic to three areas of the LDU:

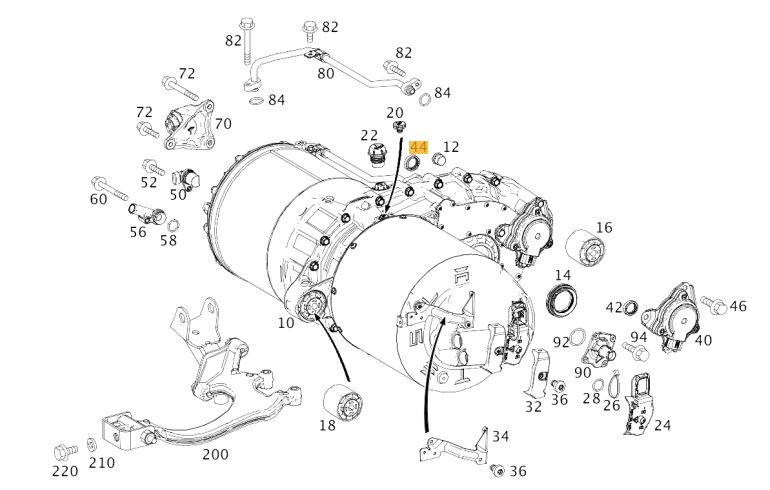

1) If the coolant mixture is not right, rust can form on the surface area where the Teflon seal sits around the rotor tube and will eventually grind a groove on the steel surface (see picture with yellow arrow). If this isn’t identified early enough the rotor / motor could be rendered scrap..

2) Coolant can get inside the motor assembly and work its way through to the power electronics. In my example I could see a trail of red coolant travelling all the way along the phase legs and into the inverter cover (the bottom of the inverter PCB showed water marks too).

3) Leaked coolant can cause corrosion of the bearings which may then leave rusty deposits to work into the spline coupler wearing it away, again, rendering the rotor / motor useless. Look closely at the bearing in this picture....

This particular motor is a spare, but I believe it was run by the previous owner with the incorrect mixture of coolant, with little to no corrosion control. It’s badly rusted inside the rotor tube which has accelerated the seal failure (rusty deposits rubbing the seal contact area as the motor spins). It’s gouged a substantial groove of about 0.25mm deep.