This will probably be a slow one, but may as well get started!

I have a 2013 Honda CRF250L m/c. It's running and road legal, but is starting to show issues with the ICE, including reduction in compression, slight leaks on valve seals, and wear on the countershaft splines - it'd need top end off and cases splitting to sort these things out. That said, that's mostly an excuse to convert to electric

Legalities for a motorcycle seem easier than a car here in the UK, so long as the frame isn't altered (easy enough, make everything bolt to engine mounts and/or existing bolt holes etc, or with clamps around frame tubes). Should just need to advise insurance, take an MoT, and return the V5 to get the fuel type changed. We'll see though...

Finding suitable conversion parts has been difficult. Very little second hand/salvage electric motorcycle parts around! And of course using car parts and de-rating results in excessive weight. New motor/controller kits are of course available, but the costs (and now, import hassles) make these difficult to justify.

The bike weighs approx. 145kg in its current form, and removing all the ICE parts saves approx. 58kg. I'd like the converted machine to be no heavier than stock. Absolute minimum is 25miles range, in hilly Wales (this is my commute) but more is of course better... I've recorded my commute, done some coasting tests etc, and calculated my CdA and rolling resistance reasonably accurately, so I also know my kW and kWh targets - 5kw gives me 57mph (a perfectly adequate cruise on this machine and these roads), and 2.8kWh capacity is absolute minimum (this accounts for decent SoC de-ratings). Voltage and gearing are as yet unknown, as they largely depend on the kV of the motor.

While searching for a suitable inverter and motor, I started looking at mild hybrid starter-generators - many recent models are pancake motors which would be difficult to package (plus lack bearings, full housing etc), but 'milder'/smaller/older hybrids are more often belt-driven - this would be ideal for a bike as they're a 'better' shape for the frame, have good bearings (belt loads are quite high) and generally include good mounts. They tend to be expensive though, but this led me on to a standard car alternator - essentially a poly-phase generator with a rectifier. These are easy to convert into a motor (cut off the rectifier, solder new wires to the connections), also have good bearings and mountings, and survive many years in a hostile environment so are rugged. The downside is that they generally require the rotor to be excited - they have two brushes and slip rings; however, as it's DC and slip rings (not a commutator) and low currents, these last ages, and don't use masses of power (a couple of watts generally). Also, the current can be varied to adjust the kV of the motor! (high current at low speeds to increase torque, lower current as speed increases to increase rpm) I believe I can treat these motor as a PMSM... and don't have to worry about cooking magnets...

As for the inverter, I've got hold of a gen1 Honda Civic IMA inverter - these seem simple to drive, and compact. I've read reports of >17kW from these. Later generations seem to be more compact (gen1 has separate HV capacitors, gen2 has the capacitor potted into the inverter case, for example).

(already removed most of the bolts before remembering photos...)

Some lovely plated copper bus bars for DC and phases. 3 400V 470uF capacitors, plus some smaller film caps for DC filtering. Current sensors on each phase and DC in. (Under the metal lid in the photo is a DC-DC converter - these have been tested to <70A, and run from 60 to 220V on the HV side.

Inside the inverter are 6 Mitsubishi IGBT drivers, and a Motorola uC... not entirely sure what it does, perhaps some protection functions.

It takes the HV bus on the two terminals at the bottom, but aside from that, there's a 12V and Gnd, one mystery output (an error signal perhaps?) and 6 inputs label UL, UH, VL, VH, WL and WH. No prizes for guessing what they are

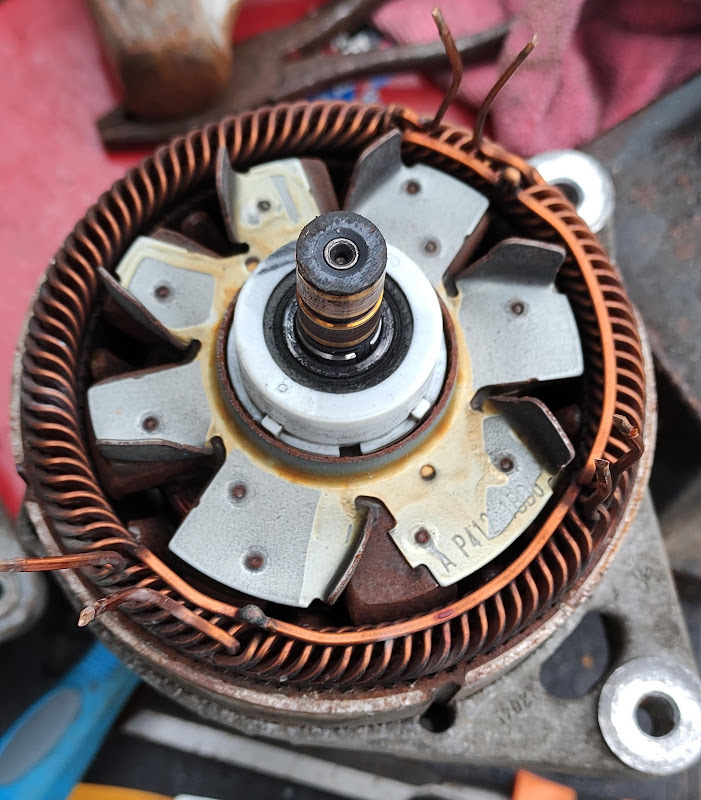

I also have a car alternator to sacrifice/convert - a 150amp unit from a Fiesta. This was perhaps overkill - it actually has 6(!) phases - smaller alternators are more likely to be three phase. Still, it'll be good to test with at least, and I can either treat it as a 75amp motor with a spare set of phases

Next task is to fix everything to a suitable board for testing, and await arrival of the openinverter board and wire it up! I'll be testing at low voltages first (a couple car batteries will do for now I think). I'll be able to work out a relationship between stall torque and rotor current, and also no load rpm at varying HV voltage and rotor current. That should give me an idea of kV range, and gearing and voltages required.