AlphaTango11 wrote: ↑Thu May 16, 2024 3:57 am

The vehicle still sometimes throws external isolation alerts when it is still (gets down to about .5MOhm, otherwise stays around 1-2MOhm). I'm an ex-Tesla service technician, and the only low isolation is at the LDU, about 1MOhm instead of >4.

Interesting that the isolation resistance is variable. Why are you certain that it's the LDU whose resistance is changing? Given the history of the Model S I would have thought that other components would be more likely to yield variable isolation (external cables, especially: a little rainwater or through the car wash with worn connector seals, and Poof! The iso goes down.).

Are you relying upon the Tesla's diagnostics for those numbers? Or, is the variability of the LDU isolation resistance being measured by, say, a Fluke 1507 Insulation Tester or equivalent? While a DMM will spot the worst of low iso stators, it isn't designed to test the isolation resistance while under HV, and that's why Tesla specs testing using a "megger". I own a 1507. It applies 500v to the stator (or whatever I'm testing) and measures the leakage/decay time with voltage applied; a DMM doesn't do that.

(ref. Tesla's Isolation Testing document

SB-10052460-6095. Not for you, but for others who will stumble across this thread later.)

Do you disconnect the LDU's HV cables and test the iso resistance of the LDU itself?

how can I resolve this low isolation if the stator is epoxied? I did not remove the rotor (which I admittedly should have done). Is it likely that the rotor needs to be removed and fully cleaned?

A couple of things here.

Cleaning the rotor isn't going to change the measured isolation resistance, because there's no electrical connection (at 500v or less) to the HV portions of the LDU. I mean, we clean the rotors, of course, when we have them out, but do they

need to be cleaned? No.

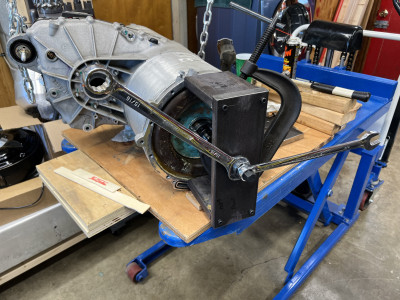

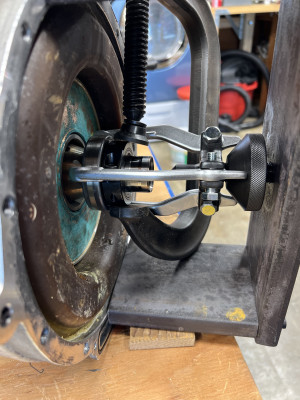

Removing the rotor wasn't a walk in the park for my recent LDU repair; I fabricated

a fixture setup to allow enough pulling force to remove the rotor with the inside bearing remaining in the case.

- LDU rotor puller split shaft collar

- LDU rotor puller

- LDU rotor puller setup

It wasn't simple or easy, but other than replacing the inside rotor brg., it allowed me access to as much of the stator as is possible. I was able to use a water-based cleaner and surfactant to remove all the coolant and corrosion byproducts from the exposed stator laminations, "wash" the exposed surfaces, blow warm air on the stator for a day, then douse everything I could with IPA (99%!

not 70%!) to further dilute any remaining water that stubbornly wouldn't evaporate.

- Tilting LDU assy. for stator cleaning

- Tilting LDU assy. for stator cleaning

Spraying IPA on a warm stator isn't exactly the safest of operations, and ventilation is really, really necessary. But IPA will merge with and dilute any water that can be accessed, and then it evaporates with a minimum of airflow and warmth.

Having said all that,

a user reports having three unsalvageable LDUs with shorted (low iso) stators right now; not all low iso stators can be "dried out". There are shops that are removing the stator from the case and rewinding/repotting them, but I have almost no info on this myself; you can readily find more on YT, etc. but I don't think of this as an economical path in the US at this time; it's certainly less expensive to find a less-soaked/higher iso stator/gearcase, than to try to rebuild a wet stator here.

---

A point that others I've discussed this with seem to overlook is that any water inside the LDU, stays in the LDU upon reassembly. It won't magically evaporate and migrate outside. For purposes of imagining water in an LDU, it's sealed. Yes, it has a couple of vents (one on the ATF/gears case; one on the stator/inverter case) but aside from thermal expansion/contraction of a couple of liters of air, no air exchange occurs, so ANY moisture left in the stator cavity etc. will remain there, further corroding things and degrading the iso resistance.

You have to dry it out, to the best of your ability, before reassembly. It will

not dry itself out later. I suspect that by not pulling your rotor and cleaning/drying as much as you could access, you may have been recycling old moisture in your LDU.

I didn't see a way to attach images . . .

It's possible that, as a member with no posts, the forum software may restrict your ability to use the Attachments feature. I know from personal experience that you can't add your Location to your profile until after you have posted at least once.