Tesla Large Drive Unit (LDU) Motor Teardown and maintenance

- asavage

- Posts: 329

- Joined: Sat May 14, 2022 10:57 pm

- Location: Oak Harbor, Washington, USA

- Has thanked: 278 times

- Been thanked: 103 times

- Contact:

Re: Tesla Large Drive Unit (LDU) Motor Teardown and maintenance

"feet/minute" is the relationship I used in our email, which is how I think about it. Whether that's a term used in the seal interface engineering world, IDK.howardc64 wrote: ↑Wed Sep 07, 2022 4:50 am Got the following info in a brief phone call

- This application (Coolant seal on a 10k RPM shaft) likely will leak after some period due to amount of surface that is engage per time period (I forgot the term he used) with water/coolant media. Basically 10k RPM = a lot of surface is engaged in unit time.

Sure, I'll front the cost of two seals, in that price range.

When I read this, Initially I agreed that the dust lip isn't needed, but after reviewing Johan's YT vids I have changed my mind. While we're not supposed to have solids flying around in the rotor cavity, in practical terms it seems more common to have debris in the rotor cavity area than I thought.

Best practise for seal installation is using a sleeve (or sleeve-like material). In Ye Olde Days, we could get away with something like masking tape or similar, but for PTFE, the stuff is notoriously un-pliable and sometimes requires a specialized installation tool/method. My predominant experience with PTFE seals is in automatic transmissions, and power steering hydraulics. PTFE is denser than typical seal materials you see in other automotive applications, but is less pliant. I've used cone-shaped install tools to introduce the seal to the shaft, but that doesn't address moving the seal into position over retainer grooves, splines, etc. where a sleeve or wrap would be a best practice.

What I see from Johan's install pics is that the encoder wheel end of the rotor is installed into the coolant manifold: a blind cavity, with no possibility of using a sleeve. Therefore, the excluder seal lip, which faces/is formed toward the "wrong" direction, must be pre-conditioned prior to offering up the manifold to be installed. The PTFE seal materials I've worked with can be deformed without damage within a very limited range, and I propose using both mild heat (say, ~150°F) plus a circular expansion tool of some kind -- there are several -- to temporarily pre-form the excluder lip to be slightly larger. As it's not meant to be a rigorous seal, we are not concerned with a perfect fit, and this seems reasonable.

Re: Tesla Large Drive Unit (LDU) Motor Teardown and maintenance

One of a seal's critical design criteria is its max surface speed in meters/sec (m/s) (or ft/min for US) RPM's need to be used in conjunction with diameters.howardc64 wrote: ↑Sun Sep 11, 2022 5:09 pm Thanks. Indeed, it was something like feet/min. Basically amount of surface area over time period which makes total sense.

So now we've got 7 seal interest which is great. However, been thinking more on doing own seal design....

- The most important factor is probably seal material (PTFE blend) and proper shaft surface roughness prep for this application (sealing water/coolant media over stainless steel shaft under 10k RPM rotation dynamic condition) There are various PTFE additives that yield different key seal properties (friction level and extrusion resistance)

- The PTFE seal will wear sacrificially. And a lipped design is desirable to maintain feeding pressure and material to the shaft surface. Shape wise, I'd imagine an experienced PTFE seal designer should know the proper lip curvature and how much lip diameter need to be smaller than the shaft to produced the right pressure+fit to seal the thin viscosity media.

- Tesla appears to have revised the seal design over last 10 years of Model S production. But seemingly have not achieved any substantive results as LDUs still leaks with regularity.

From SKF;

larger diameter shafts can accommodate higher circumferential speeds than shafts with smaller diameters. This is because the cross section of the shaft does not increase linearly with the increase in diameter but by the square of the increase in diameter. Therefore, the heat dissipation of a large shaft is much better than that of a small shaft.

- muehlpower

- Posts: 574

- Joined: Fri Oct 11, 2019 10:51 am

- Location: Germany Fürstenfeldbruck

- Has thanked: 12 times

- Been thanked: 103 times

Re: Tesla Large Drive Unit (LDU) Motor Teardown and maintenance

That's not true. There are twist-free ground rings for use with sealing rings. I hope google translates this correctly.

IR30x35x16-EGS or IR30x35x12.5-EGS

Re: Tesla Large Drive Unit (LDU) Motor Teardown and maintenance

You had a question previously following your conversation with a seal supplier - I was just trying to help.

A 30mm seal at;

10,000 rpm has a surface speed of 15.7m/s

15,000 rpm has a surface speed of 23.5m/s

18,000 rpm has a surface speed of 28.3m/s

Limit the LDU to 10k and just looking at m/s it looks like a good Fluoro rubber seal is suitable. However it gets more 'complicated' as I would think 1,2 & 4 conditions below also apply to the LDU;

from here:The values obtained from the diagram 4 should be reduced if:

1; radial shaft seals with an auxiliary, contacting lip are used

2; lubrication is inadequate or grease lubrication is used, i.e. when underlip temperatures increase due to poor heat dissipation

3; the counterface does not meet surface finish or running accuracy requirements

4; there is a pressure differential across the seal

https://www.skf.com/group/products/indu ... ble-speeds

Re: Tesla Large Drive Unit (LDU) Motor Teardown and maintenance

@SuperV8: Thanks for that graph!

Increase of the shaft diameter is probably not a solution in this case. Here's why: Start with the requirement that the LDU must sustain a continuous maximum speed of for example 100 mph (161 km/h). This corresponds to 11479 RPM, given an assumed tire diameter of 724mm and a given fixed LDU gear box reduction factor of 9.73. The graph below shows that at a given shaft diameter of 30mm, a fluoro rubber seal results in a maximum of 12420 RPM* (blue dashed line), so the 100 mph requirement is satisfied. Next, the graph shows that an increase of the shaft diameter to 40mm results in a reduction of the maximum RPM value from 12420 to ~11000 (red dashed line), so now the requirement is not met anymore. Also the addition of a sleeve introduces a thermal contact resistance between shaft and sleeve, which would lower thermal conductivity in shaft radial direction, which is not what you want.

*assuming oil or grease lubricant, which we do not have; equals the spec of HMS 5 seal

Increase of the shaft diameter is probably not a solution in this case. Here's why: Start with the requirement that the LDU must sustain a continuous maximum speed of for example 100 mph (161 km/h). This corresponds to 11479 RPM, given an assumed tire diameter of 724mm and a given fixed LDU gear box reduction factor of 9.73. The graph below shows that at a given shaft diameter of 30mm, a fluoro rubber seal results in a maximum of 12420 RPM* (blue dashed line), so the 100 mph requirement is satisfied. Next, the graph shows that an increase of the shaft diameter to 40mm results in a reduction of the maximum RPM value from 12420 to ~11000 (red dashed line), so now the requirement is not met anymore. Also the addition of a sleeve introduces a thermal contact resistance between shaft and sleeve, which would lower thermal conductivity in shaft radial direction, which is not what you want.

*assuming oil or grease lubricant, which we do not have; equals the spec of HMS 5 seal

Disclaimer: Despite all efforts, all (which I write) should be conservatively interpreted as a poorly informed, error-prone, non-expert opinion that is subject to continuous change, especially in this age of hyper-specialization and newly gained insights.

- Boxster EV

- Posts: 434

- Joined: Fri Jul 26, 2019 9:32 pm

- Location: UK

- Has thanked: 35 times

- Been thanked: 27 times

Re: Tesla Large Drive Unit (LDU) Motor Teardown and maintenance

In post two of this thread I describe how I removed the rotor. Method is Heath Robinson but works.Can't Get Rotor out

- Boxster EV

- Posts: 434

- Joined: Fri Jul 26, 2019 9:32 pm

- Location: UK

- Has thanked: 35 times

- Been thanked: 27 times

Re: Tesla Large Drive Unit (LDU) Motor Teardown and maintenance

That’s basically it. It’ll just require a shock / jolt to release the spline. The outer wood blocks will make contact with the motor casing, allowing the rotor’s vertical momentum to fall further and break free. Just ensure there’s something there to catch the rotor’s fall and not damage anything.My setup at the moment

https://photos.app.goo.gl/bLk8ut9ZBYKDt7DX8

https://photos.app.goo.gl/2szAt6ZSzLzh7wWa9

Lets hope I don't destroy the inner ceramic bearings and/or have the bearing stay behind.

- asavage

- Posts: 329

- Joined: Sat May 14, 2022 10:57 pm

- Location: Oak Harbor, Washington, USA

- Has thanked: 278 times

- Been thanked: 103 times

- Contact:

Re: Tesla Large Drive Unit (LDU) Motor Teardown and maintenance

There are several layers of defence we can apply to the overall coolant leak issue. Replacing the seal et al will (usually, supposedly, temporarily?) stop coolant ingress. Great, problem solved . . . for now.

Based on historic trends, we're making a reasonable assumption that the rotor seal will leak again. We can put in place protective measures to slow the damage caused by a repeat incident.

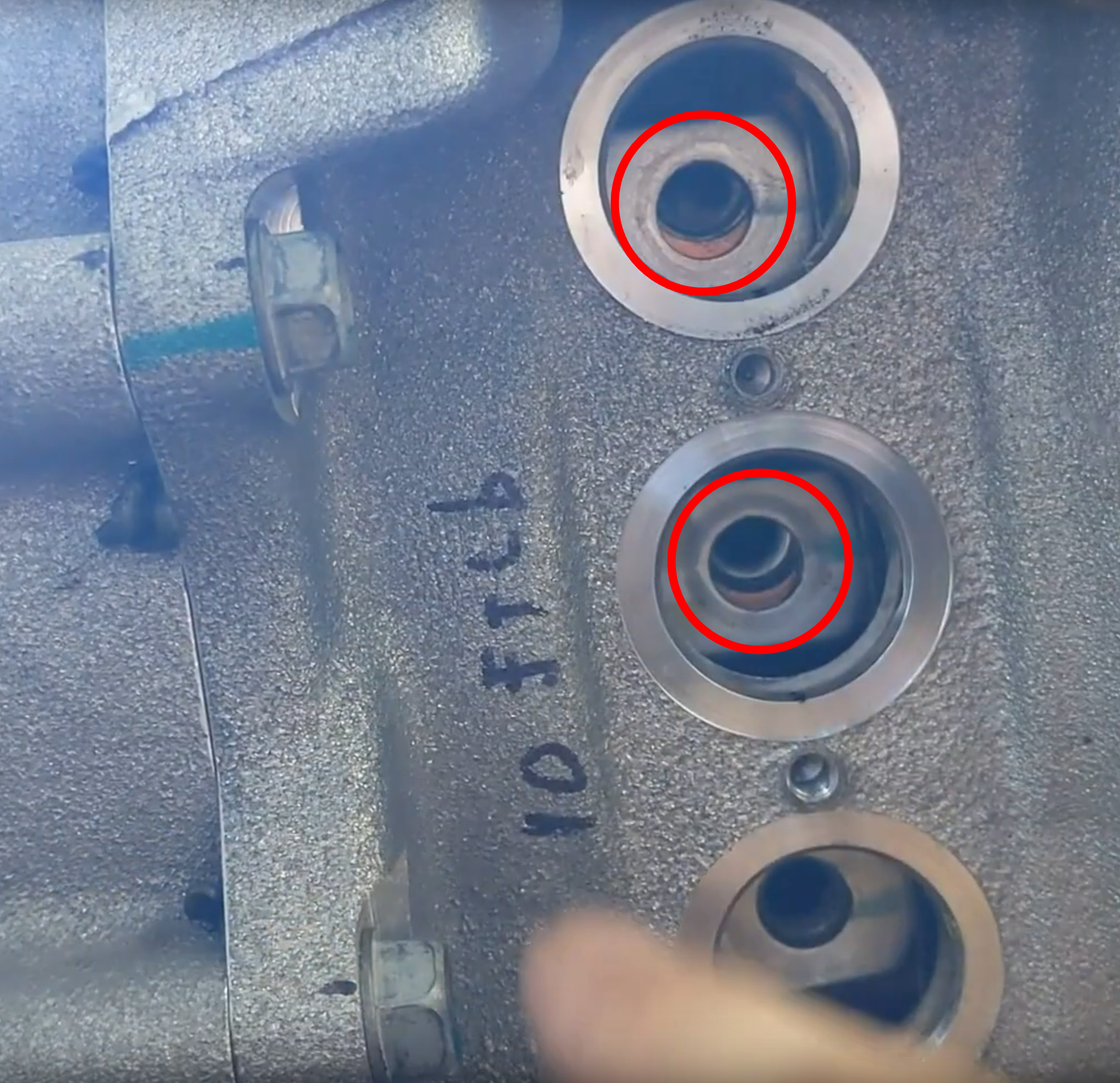

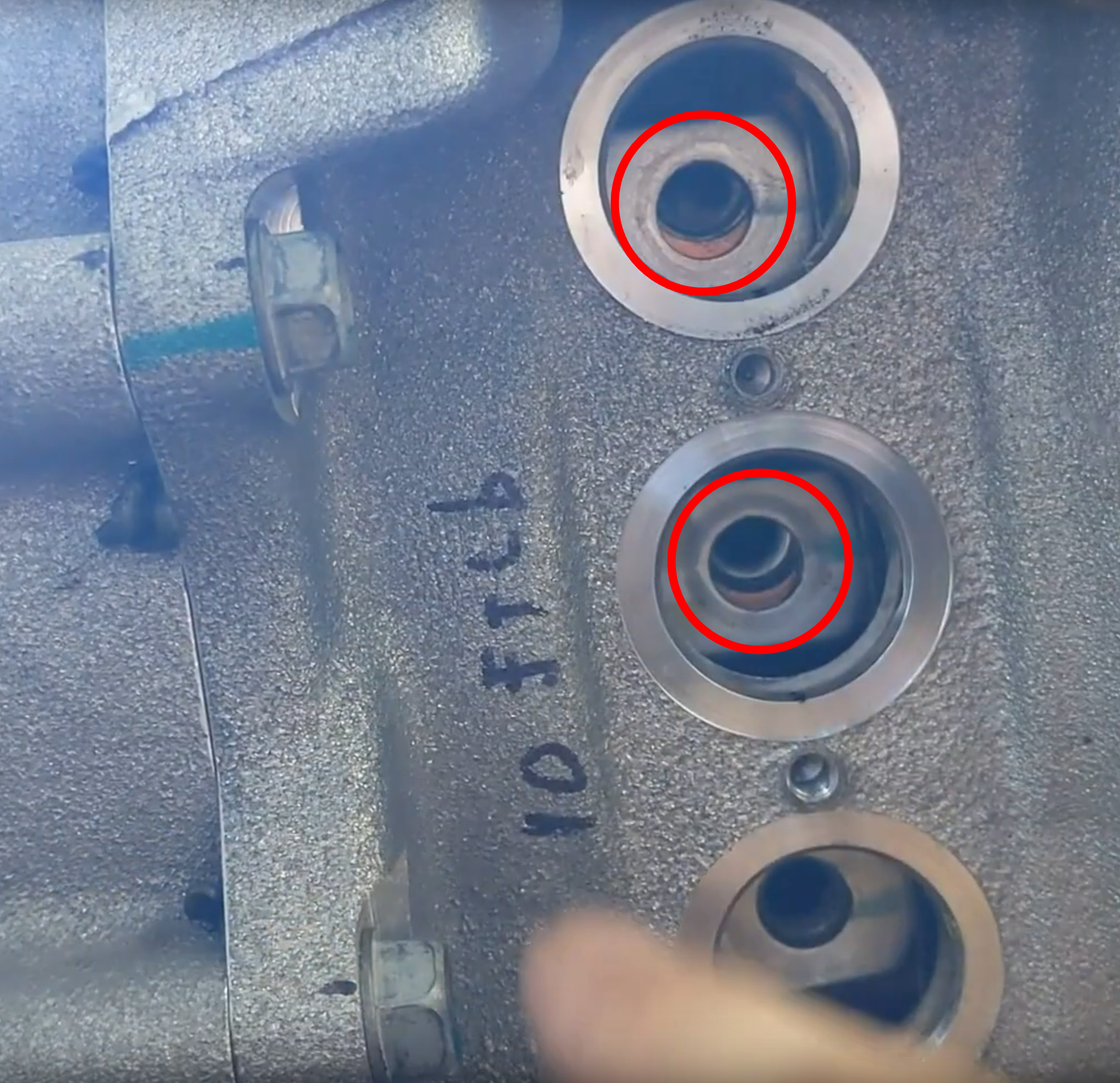

I think that the mods that Johan performed on his repair are fine, and I like that he walked us through his assumptions and reasoning. Most of the screengrabs below are from one of his excellent YT vids on this topic.

Possible defensive measures that could be incorporated into a seal repair process include:

1) Seal off the rotor side from the inverter side.

Alex @ QCP says that he installs a silicone gasket there to replace a paper gasket (not clear to me what that means) and then uses Form-A-Gasket (a Permatex-branded RTV [Room Temperature Vulcanize] silicone-based sealant), to fill that cavity. I think RTV would work as well as Johan's two-part potting compound, though it might not look quite as nice

The separate 4-wire bundle needs its own, separate application of sealant as well, I think.

One problem that arose during Johan's assembly was that a jig is probably needed to hold the bus bars in the proper position, prior to potting using his pour method -- and probably is a good idea using a caulking-style silicone injection method. He found slight misalignment of the bus bars with the inverter connector locations during assembly, a very easy thing to overlook. The bars/connector pads misalignment shown below is not parallax error, and Johan had to persuade the bars to move to the correct locations, possibly compromising the potting material's seal.

So, a jig.

2) Create a weep hole under the seal, to dump overboard seal leakage right at the first leak point.

Funny, back in the day, every automotive water pump had a weep hole between the coolant seal and the pump shaft bearing.

On the Tesla LDU, installing a weep hole is a well-trod path that others have done successfully. Drain line or not -- and if so, the type of fitting -- are a preference/optional item, but just providing a safer place for leakage to exit is a very good start:

3) Create a weep hole/inspection hole/sensor hole in the bottom of the stator housing.

This is a hole at a low point in the rotor cavity, where a one-wire sensor can be installed in a eg 5mm hole, to provide an in-car warning annunciator (light, buzzer, SMS msg, etc.); or, it can be used as an additional drain point.

AFAIK, this was the first documented drain location/method for an LDU.

https://www.myrav4ev.com/forum/viewtopi ... 419#p29419

https://www.youtube.com/watch?v=ps2gha4w5YE[url]

4) Seal the existing vent balance hole on the rotor end support (between reluctor chamber and rotor cavity), and install a second external vent, Toyota 33197-0R010 (USD$8 ea.). Aerosolized coolant that being whipped about by the reluctor is thus slowed from moving through the OEM vent hole to the rotor cavity, giving it time to find its way to the weep hole that was installed:

5) Add a third external vent to rotor end support, between rotor cavity and outside:

6) Add an inverter-side drain.

I'm of two minds on inverter drains.

QCP is selling their "drain kit" that taps the inverter side. But, I've read no evidence that coolant leaks have ever started on the inverter side, but there seems to be at least one instance where the gearbox lubricant escaped to the inverter. So, while I'm not particularly worried about monitoring the inverter side for coolant, coolant in the inverter isn't the only thing that needs external validation

7) Less damaging coolant.

An idea that has been brought up is to discontinue cooling with a water-based coolant (ie use oil, or a glycol-based waterless coolant). Internal leaks would then cause less immediate, and less expensive, damage, giving more time for a leak to be detected. Using waterless coolant will make electronic detection of a leak challenging, as the current leak detection schemes are either conductivity- or vertical-level based. Is there an electronic glycol detector?

Based on historic trends, we're making a reasonable assumption that the rotor seal will leak again. We can put in place protective measures to slow the damage caused by a repeat incident.

I think that the mods that Johan performed on his repair are fine, and I like that he walked us through his assumptions and reasoning. Most of the screengrabs below are from one of his excellent YT vids on this topic.

Possible defensive measures that could be incorporated into a seal repair process include:

1) Seal off the rotor side from the inverter side.

Alex @ QCP says that he installs a silicone gasket there to replace a paper gasket (not clear to me what that means) and then uses Form-A-Gasket (a Permatex-branded RTV [Room Temperature Vulcanize] silicone-based sealant), to fill that cavity. I think RTV would work as well as Johan's two-part potting compound, though it might not look quite as nice

The separate 4-wire bundle needs its own, separate application of sealant as well, I think.

One problem that arose during Johan's assembly was that a jig is probably needed to hold the bus bars in the proper position, prior to potting using his pour method -- and probably is a good idea using a caulking-style silicone injection method. He found slight misalignment of the bus bars with the inverter connector locations during assembly, a very easy thing to overlook. The bars/connector pads misalignment shown below is not parallax error, and Johan had to persuade the bars to move to the correct locations, possibly compromising the potting material's seal.

So, a jig.

2) Create a weep hole under the seal, to dump overboard seal leakage right at the first leak point.

Funny, back in the day, every automotive water pump had a weep hole between the coolant seal and the pump shaft bearing.

On the Tesla LDU, installing a weep hole is a well-trod path that others have done successfully. Drain line or not -- and if so, the type of fitting -- are a preference/optional item, but just providing a safer place for leakage to exit is a very good start:

3) Create a weep hole/inspection hole/sensor hole in the bottom of the stator housing.

This is a hole at a low point in the rotor cavity, where a one-wire sensor can be installed in a eg 5mm hole, to provide an in-car warning annunciator (light, buzzer, SMS msg, etc.); or, it can be used as an additional drain point.

AFAIK, this was the first documented drain location/method for an LDU.

https://www.myrav4ev.com/forum/viewtopi ... 419#p29419

https://www.youtube.com/watch?v=ps2gha4w5YE[url]

4) Seal the existing vent balance hole on the rotor end support (between reluctor chamber and rotor cavity), and install a second external vent, Toyota 33197-0R010 (USD$8 ea.). Aerosolized coolant that being whipped about by the reluctor is thus slowed from moving through the OEM vent hole to the rotor cavity, giving it time to find its way to the weep hole that was installed:

5) Add a third external vent to rotor end support, between rotor cavity and outside:

6) Add an inverter-side drain.

I'm of two minds on inverter drains.

QCP is selling their "drain kit" that taps the inverter side. But, I've read no evidence that coolant leaks have ever started on the inverter side, but there seems to be at least one instance where the gearbox lubricant escaped to the inverter. So, while I'm not particularly worried about monitoring the inverter side for coolant, coolant in the inverter isn't the only thing that needs external validation

7) Less damaging coolant.

An idea that has been brought up is to discontinue cooling with a water-based coolant (ie use oil, or a glycol-based waterless coolant). Internal leaks would then cause less immediate, and less expensive, damage, giving more time for a leak to be detected. Using waterless coolant will make electronic detection of a leak challenging, as the current leak detection schemes are either conductivity- or vertical-level based. Is there an electronic glycol detector?

- asavage

- Posts: 329

- Joined: Sat May 14, 2022 10:57 pm

- Location: Oak Harbor, Washington, USA

- Has thanked: 278 times

- Been thanked: 103 times

- Contact:

Re: Tesla Large Drive Unit (LDU) Motor Teardown and maintenance

Yeah, it seems that Tesla dropped installation of the Aegis ring at some point. Multiple reports of Tesla-supplied reman units have none installed, so it's not just 3rd-party shops or DIYers leaving them out.

Ferrous material on the three magnets means that's ferrous material not in solution, and it's therefore not harming anything. There's no need to remove it or clean the big magnet, but as you noted it's also not going to come out with an oil change. Cleaning the fill/drain magnet(s) is OK, but there's plenty of magnetic surface to take the bits out of the moving lubricant, even with a thick coating of particles.howardc64 wrote: ↑Wed Sep 21, 2022 6:40 pm Metallic Mud

[ . . . ]

I think this suggest a higher gearbox oil change frequency. Since its only 1.5 qt of Dex6 ATF and there is ample mud at 32k on my reman RevQ. Probably worth changing it annually along with speed sensor and inverter B+ B- port checks for coolant leaks. However, the big magnet next to oil pickup tube captures so much mud that ATF change probably doesn't get any of that out. Only cracking open the gearbox can do that.

Now, what's causing all this loose ferrous material, and does that need addressing, those are different concerns, but I wouldn't worry a bit about removing what's on the magnet. To me, on an uncomplicated gearbox like this, that seems like a lot of particles. I sure want to point my finger at the rotor's pinion gear, because that's where things are moving fastest, and where stray induced currents could be, but I don't have the education to back up my guess.

Oil Change Interval (OCI) is a hot topic everywhere, like your favorite brand of oil/spark plug/coolant. I will note here that anybody's ATF is going to be pretty darned good quality these days, it's pretty much all synthetic -- which, done right, means the oil molecules are built-up from natural gas base stock, so no crud or incomplete chains in the oil to being with -- and ATF is specified for some of the most demanding applications you'll find outside of aerospace.

ATF doesn't have a lot of HD EP qualities, but it holds up in planetary gearsets in 1000+ HP drag cars (I know, I know: Apples to Oranges) and I do not doubt that little degradation takes place in the LDU's ATF, even if you doubled the OCI. Typically, either overheating or foaming plus overheating are the only ways to seriously degrade ATF. Additives . . . maybe. Anti-foaming agents probably are not forever, and foaming is a real possibility in this box.

EP is needed in the diff gears, but usually isn't for planetaries: there's almost no wiping action going on, nothing comparable to typical RWD hypoid gears, for example.

Note that Tesla does have a externally serviceable filter on their later DU designs, so they think it's needed. Oil is cheap, and any oil change monkey can do the job, so it's not expensive to have done. So, sure, change the oil frequently, it's not hard to DIY, or it's not expensive to have done for you. But I won't lose any sleep over having a 50k OCI on it, even if it's only 1.6l. It doesn't cook in the LDU.

- asavage

- Posts: 329

- Joined: Sat May 14, 2022 10:57 pm

- Location: Oak Harbor, Washington, USA

- Has thanked: 278 times

- Been thanked: 103 times

- Contact:

Re: Tesla Large Drive Unit (LDU) Motor Teardown and maintenance

I ordered a single gallon of Evans waterless coolant, which will arrive early next week. The PWM doo-dad will arrive . . . today, Amazon says . . . [goes out and checks mailbox] . . . yup, got it.

I wonder where I put that Tesla coolant pump . . . found it, in the "RAV4 EV" tote.

[Unscrews cover]

Ugh. I should have pulled the impeller cover off before: the impeller is hard plastic, no chance of this being adversely affected by high-viscosity coolant.

I wonder where I put that Tesla coolant pump . . . found it, in the "RAV4 EV" tote.

[Unscrews cover]

Ugh. I should have pulled the impeller cover off before: the impeller is hard plastic, no chance of this being adversely affected by high-viscosity coolant.

Re: Tesla Large Drive Unit (LDU) Motor Teardown and maintenance

Personally I'm not a fan of 'waterless coolant' It has a lower heat capacity than water meaning for your same pump speed and radiator size your motor/inverter and what ever else gets cooled will be running at a higher temperature.

Re: Tesla Large Drive Unit (LDU) Motor Teardown and maintenance

Not sure I understand your point here regarding ratios?howardc64 wrote: ↑Wed Sep 21, 2022 6:40 pm This gearbox has 10:1 ratio. Starting with high RPM motor all the way to driving the half shafts. Its a wide range to trade off efficiency (thinner ATF) to high wear protection (multi weight gear oil for rear diffs such as 80w-90) LDU also has no damper for the applied torque (ICE's gradual torque curve, torque converter/clutch/clutch packs) Tesla went with thin ATF for efficiency on a 10x ratio gear box. Seems like less wear protection is the required tradeoff.

For reference, FWD ICE automatics are usually 0.5+ to 3-4x ratio and motor RPM at 1/2 to 1/3 of Tesla LDU at highway speeds. Much less aggressive ratio to use ATF. Some automatic gear boxes use thick multi weight gear oil for final diff gears (which change speeds at every turn)

I think this suggest a higher gearbox oil change frequency. Since its only 1.5 qt of Dex6 ATF and there is ample mud at 32k on my reman RevQ. Probably worth changing it annually along with speed sensor and inverter B+ B- port checks for coolant leaks. However, the big magnet next to oil pickup tube captures so much mud that ATF change probably doesn't get any of that out. Only cracking open the gearbox can do that.

The Tesla 9.7344:1 gear reduction is total gear reduction including differential reduction gear ratio.

The 3-4:1 you mention for the ICE auto transmission is NOT including any final drive gear reduction. Many ICE drivetrains can have 10-15:1 total gear reduction in the 1st & 2nd gears.

ATF is/can be a very high quality oil - generally much more expensive than any MTF made from better quality oil base stocks.

Rear differentials are hypoid gear and have totally different oil requirements than front differentials in transverse ICE cars - which is why they need different/separate oil. Transverse transmissions are quite happy to share their oil between the reduction gears and the differential.

- asavage

- Posts: 329

- Joined: Sat May 14, 2022 10:57 pm

- Location: Oak Harbor, Washington, USA

- Has thanked: 278 times

- Been thanked: 103 times

- Contact:

Re: Tesla Large Drive Unit (LDU) Motor Teardown and maintenance

Lots of people are not fans of waterless coolants for that reason: with water being "1", glycols typically have a thermal capacity of around .68-.72. In the ICE world so very many people seem to be chasing cures for overheating, and waterless coolant just isn't the right fix for almost all those situations, so it's gotten a bad rep.

However, in the LDU I don't think we need a whole lot of heat-moving capacity; there's just not a lot of heat to be moved, and unlike a legacy ICE situation, the pump capacity is not limited by the idle speed of the ICE; Tesla's thermal management can push the fluid as fast as is needed regardless of other conditions.

I assume that most people are not going to go this route, but it's a valid idea for harm reduction of the expensive bits.