My LDU rebuild has been done for a few weeks now. Used Ceimin yellow triple lip on 600->1500 grit prepped shaft surface. 400mi and no leak on speed sensor so far.

Am still chasing quality brand PTFE seal source for the community. Sharing a status update. Prior update here.

https://openinverter.org/forum/viewtopi ... 858#p46858 Quick summary is no new source but can offer a Parker custom seal PN that others can also chase down if interested

Water Pump Style Ring Faced Seal

Found a company

https://www.ergoseal.com/ that Tesla tier suppliers contacted for seal design a couple of years ago. They showed a drawing of a water pump style seal but never got beyond drawing proposal phase. So DIY community can't afford the dev+test cost.

I'm no water pump seal expert (nor a PTFE/FKM seal expert either haha) but this solution seems quite challenging to me. Regular water pump seal is factory machine assembled into the water pump along with leak drain chambers/weep drain channels AND an additional barrier of some sort between leak chamber and bearing.

https://www.agcoauto.com/content/news/p2_articleid/190 LDU's structure seems to be quite challenging for this from 2 areas

- Space is ultra tight for a water pump type seal's structure and its internal components along the axial direction

- Likely need to assembly the seal by mating its 2 halves so each halve can be water tight pressed onto their mounting structure (coolant shaft, coolant manifold) Any high precision assembly tolerance is not achievable with the way coolant manifold mount onto the shaft.

Regardless, the big barrier is can't pay for custom dev+test.

Triple Lip Seal

Struck out at Saint-Gobain's custom seal division on prior update. Sounds like they are bound up by Tesla in some way. Reached out to Parker-Hannifin's similar dept (Engineered Polymer Systems - EPS). Talked to 2x application engineer, 2x customer support ladies. 1x local distributor. Dead end so far but sharing a PN and spec from Parker's custom catalog

EPS catalog 5340 (PTFE seal) Dated 2008-2018

https://www.parker.com/literature/Engin ... 0_2008.pdf EPS catalog 5350 (Rotary seal, inclusive of PTFE) Dated 2006

https://www.parker.com/literature/Engin ... s/5350.pdf Both catalog allows choosing from many parameters for desired spec. Many overlap info between the 2 catalog but also complementary info in PTFE material property tables.

Provide the following seal PN to distributor to quote below. They've not replied after a couple of weeks so will need to follow up.

M 0615 LDE 1250 03000 080 N

Untangling this spec is found on page 8-2 of 5340

M=metric

0615 = Proprietary low wear PTFE material

8-6 3-2 3-4 3-5 8-6 of 5340

9-8 of 5350 include min shaft hardness (we can't determine without testing so just guess something softer rather than harder 25Rc for 0615)

LDE = LD (dual lip) + E (excluder)

1250 = 12.5mm which is half of 55mm (OD) - 30mm (ID)

03000 = 30mm ID

080 = 8mm width (don't know how far lips will extend beyond seal width (Ceimin stretches to nearly 12mm leaving 1mm+ of margin left on the shaft to margin both coolant and excluder lip) see pdf doc here (

https://teslamotorsclub.com/tmc/posts/7185566/ )

N = NBR for o-ring. Can inquire about Parker's special coolant resistant FKM later which surely requires more Parker engineering discussion.

https://www.parker.com/Literature/O-Rin ... G_5040.pdf Calling Parker EPS (# on catalog) can not reach app engineering directly but support ladies will route. 2 application engineers I spoke to wasn't too helpful. They mostly confirmed what I already knew and one said just go with OEM thinking OEM has done their homework. They confirmed the following

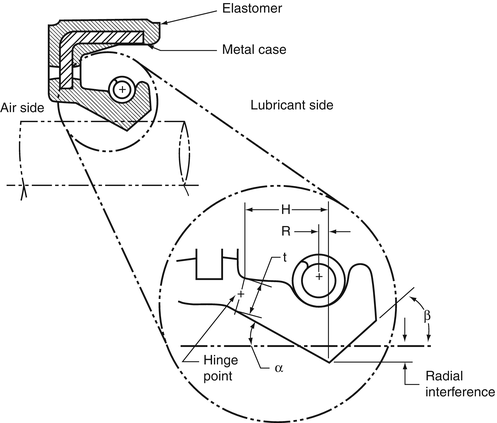

- Lathe cut depending on material and spec. Diameter of each lips are automatically determined by ID spec (and maybe material?) Ceimin seals is probably like this. Primary coolant seal lip is tightest at 26.5mm unstretched and excluder lip at 28mm unstretched (

https://teslamotorsclub.com/tmc/posts/7185566/ ))

- No pump aid structure (same as Ceimin and Tesla single lip PTFE OEM)

- No concentric rings to aid bending (same as Ceimin) Tesla single lip PTFE OEM has rings

- Caged seals are discontinued (shown on 5340 catalog) so have to go with o-ringed on OD and probably can sealant mount into bore.

====

Also want to note the triple lip PTFE seal installation is a highly error prone step. Almost impossible to not fold the excluder lip unless you know the assembly tricks. The same link provided above outline this in full detail

https://teslamotorsclub.com/tmc/posts/7185566/