Re: Tesla Large Drive Unit (LDU) Motor Teardown and maintenance

Posted: Fri Sep 09, 2022 6:37 pm

DELETED

openinverter Community

https://openinverter.org/forum/

"feet/minute" is the relationship I used in our email, which is how I think about it. Whether that's a term used in the seal interface engineering world, IDK.howardc64 wrote: ↑Wed Sep 07, 2022 4:50 am Got the following info in a brief phone call

- This application (Coolant seal on a 10k RPM shaft) likely will leak after some period due to amount of surface that is engage per time period (I forgot the term he used) with water/coolant media. Basically 10k RPM = a lot of surface is engaged in unit time.

Sure, I'll front the cost of two seals, in that price range.

When I read this, Initially I agreed that the dust lip isn't needed, but after reviewing Johan's YT vids I have changed my mind. While we're not supposed to have solids flying around in the rotor cavity, in practical terms it seems more common to have debris in the rotor cavity area than I thought.

One of a seal's critical design criteria is its max surface speed in meters/sec (m/s) (or ft/min for US) RPM's need to be used in conjunction with diameters.howardc64 wrote: ↑Sun Sep 11, 2022 5:09 pm Thanks. Indeed, it was something like feet/min. Basically amount of surface area over time period which makes total sense.

So now we've got 7 seal interest which is great. However, been thinking more on doing own seal design....

- The most important factor is probably seal material (PTFE blend) and proper shaft surface roughness prep for this application (sealing water/coolant media over stainless steel shaft under 10k RPM rotation dynamic condition) There are various PTFE additives that yield different key seal properties (friction level and extrusion resistance)

- The PTFE seal will wear sacrificially. And a lipped design is desirable to maintain feeding pressure and material to the shaft surface. Shape wise, I'd imagine an experienced PTFE seal designer should know the proper lip curvature and how much lip diameter need to be smaller than the shaft to produced the right pressure+fit to seal the thin viscosity media.

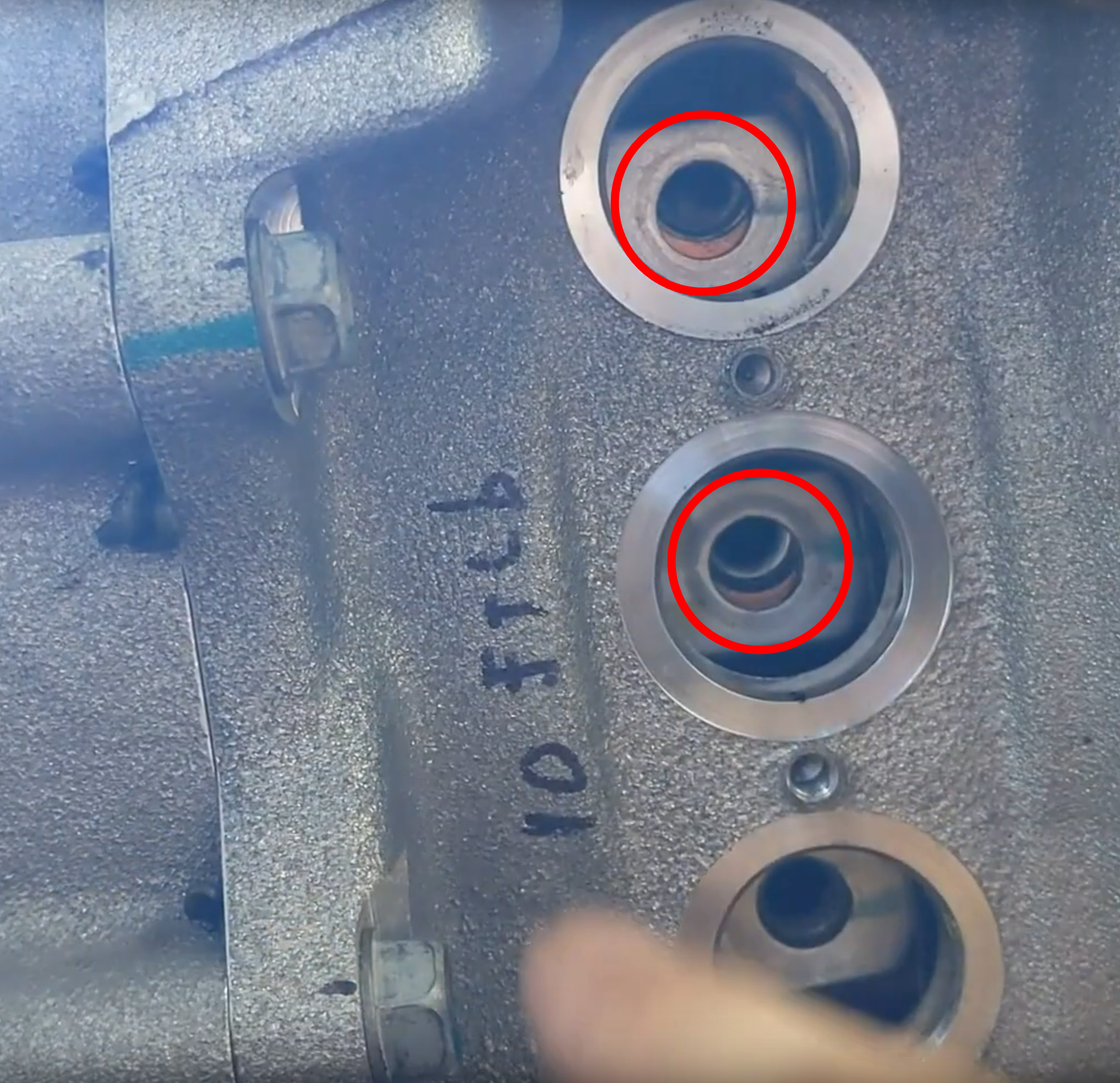

- Tesla appears to have revised the seal design over last 10 years of Model S production. But seemingly have not achieved any substantive results as LDUs still leaks with regularity.

You had a question previously following your conversation with a seal supplier - I was just trying to help.

from here:The values obtained from the diagram 4 should be reduced if:

1; radial shaft seals with an auxiliary, contacting lip are used

2; lubrication is inadequate or grease lubrication is used, i.e. when underlip temperatures increase due to poor heat dissipation

3; the counterface does not meet surface finish or running accuracy requirements

4; there is a pressure differential across the seal

In post two of this thread I describe how I removed the rotor. Method is Heath Robinson but works.Can't Get Rotor out

That’s basically it. It’ll just require a shock / jolt to release the spline. The outer wood blocks will make contact with the motor casing, allowing the rotor’s vertical momentum to fall further and break free. Just ensure there’s something there to catch the rotor’s fall and not damage anything.My setup at the moment

https://photos.app.goo.gl/bLk8ut9ZBYKDt7DX8

https://photos.app.goo.gl/2szAt6ZSzLzh7wWa9

Lets hope I don't destroy the inner ceramic bearings and/or have the bearing stay behind.

Yeah, it seems that Tesla dropped installation of the Aegis ring at some point. Multiple reports of Tesla-supplied reman units have none installed, so it's not just 3rd-party shops or DIYers leaving them out.

Ferrous material on the three magnets means that's ferrous material not in solution, and it's therefore not harming anything. There's no need to remove it or clean the big magnet, but as you noted it's also not going to come out with an oil change. Cleaning the fill/drain magnet(s) is OK, but there's plenty of magnetic surface to take the bits out of the moving lubricant, even with a thick coating of particles.howardc64 wrote: ↑Wed Sep 21, 2022 6:40 pm Metallic Mud

[ . . . ]

I think this suggest a higher gearbox oil change frequency. Since its only 1.5 qt of Dex6 ATF and there is ample mud at 32k on my reman RevQ. Probably worth changing it annually along with speed sensor and inverter B+ B- port checks for coolant leaks. However, the big magnet next to oil pickup tube captures so much mud that ATF change probably doesn't get any of that out. Only cracking open the gearbox can do that.

Personally I'm not a fan of 'waterless coolant' It has a lower heat capacity than water meaning for your same pump speed and radiator size your motor/inverter and what ever else gets cooled will be running at a higher temperature.

Not sure I understand your point here regarding ratios?howardc64 wrote: ↑Wed Sep 21, 2022 6:40 pm This gearbox has 10:1 ratio. Starting with high RPM motor all the way to driving the half shafts. Its a wide range to trade off efficiency (thinner ATF) to high wear protection (multi weight gear oil for rear diffs such as 80w-90) LDU also has no damper for the applied torque (ICE's gradual torque curve, torque converter/clutch/clutch packs) Tesla went with thin ATF for efficiency on a 10x ratio gear box. Seems like less wear protection is the required tradeoff.

For reference, FWD ICE automatics are usually 0.5+ to 3-4x ratio and motor RPM at 1/2 to 1/3 of Tesla LDU at highway speeds. Much less aggressive ratio to use ATF. Some automatic gear boxes use thick multi weight gear oil for final diff gears (which change speeds at every turn)

I think this suggest a higher gearbox oil change frequency. Since its only 1.5 qt of Dex6 ATF and there is ample mud at 32k on my reman RevQ. Probably worth changing it annually along with speed sensor and inverter B+ B- port checks for coolant leaks. However, the big magnet next to oil pickup tube captures so much mud that ATF change probably doesn't get any of that out. Only cracking open the gearbox can do that.

Lots of people are not fans of waterless coolants for that reason: with water being "1", glycols typically have a thermal capacity of around .68-.72. In the ICE world so very many people seem to be chasing cures for overheating, and waterless coolant just isn't the right fix for almost all those situations, so it's gotten a bad rep.